High-efficiency filters are widely used and are usually used in fields with high requirements for cleanliness. As one of air filters, W-type high-efficiency filters are used, so what are the requirements for its installation process?

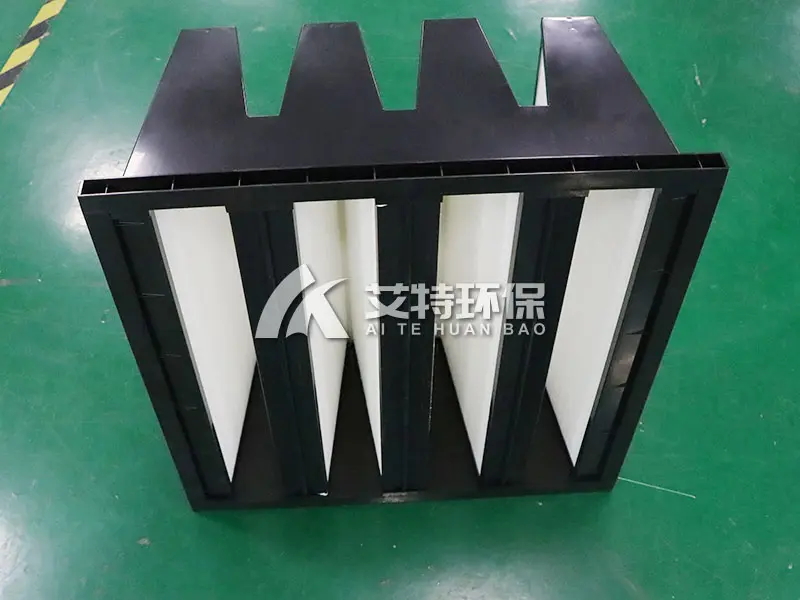

W-type high-efficiency filters are usually used in various air-conditioning equipment, automotive air-conditioning filters and other fields. It can filter out powdery, columnar, granular and other particles of various specifications.

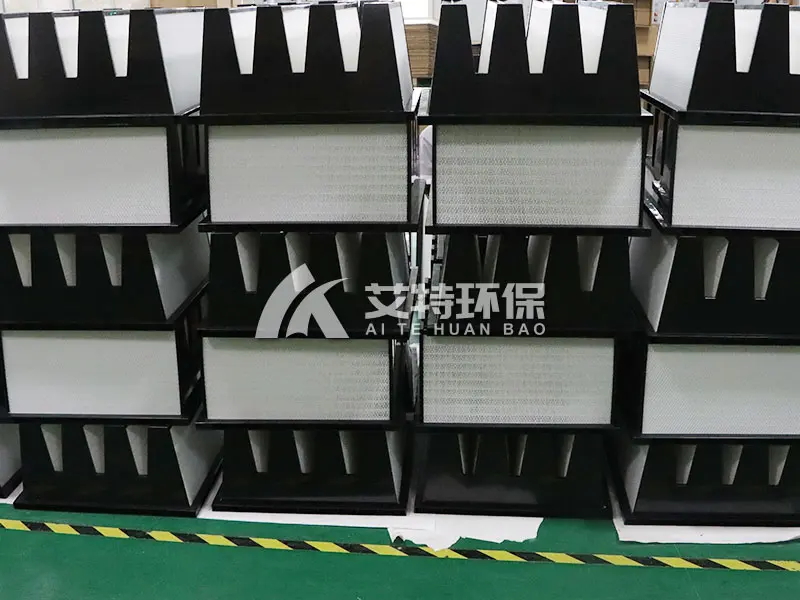

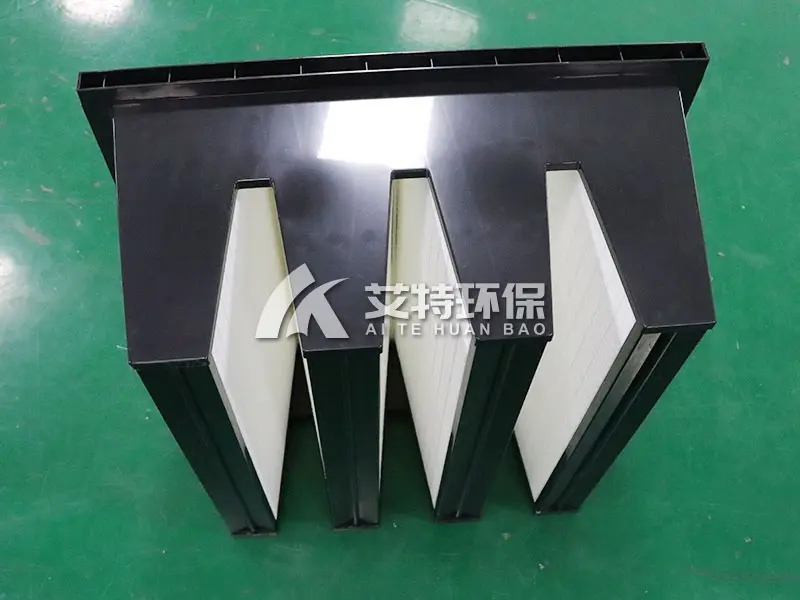

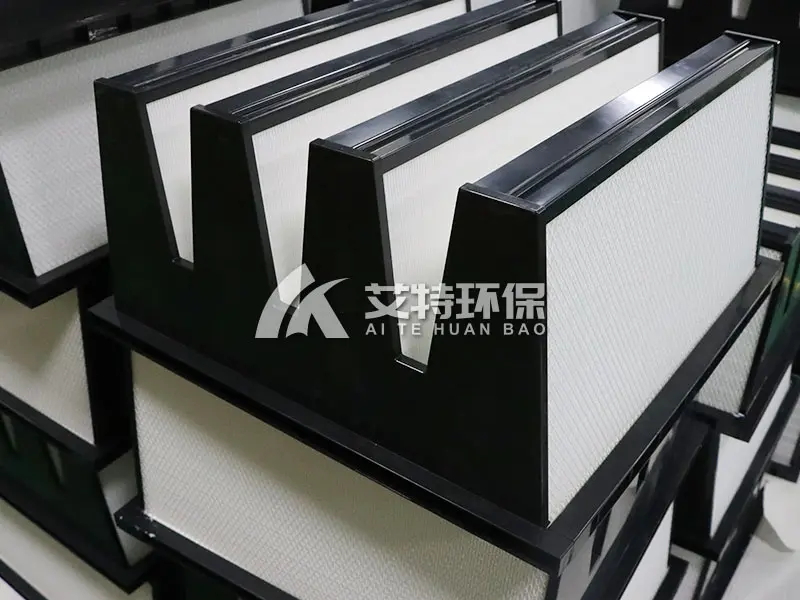

The W high-efficiency filter has a large surface area and can absorb various harmful gases and fine dust particles that are invisible to the naked eye. This device is light in weight, large in air volume and compact in structure, so it is suitable for variable air volume or turbulent wind speed systems. , coupled with its V-shaped design and no partition design, it increases the filtering area, and has low pressure loss, which can also reduce energy consumption and operating costs.

Installation requirements for W type high efficiency filter:

1. Before installing the W-type high-efficiency filter, the clean room and purification air-conditioning system need to meet the standard cleanliness requirements, and then carry out trial operation, which requires continuous trial operation for more than 12 hours. After cleaning, the filter should be installed immediately and the clean room should be wiped again.

2. The frame for installing the filter needs to be smooth, because the flatness of the installation frame of each W-type high-efficiency filter cannot exceed one meter. Make sure that the arrow on the outside of the filter is aligned with the flow direction. If it is installed vertically, the filter paper The crease needs to be perpendicular to the ground.

3. When installing the W-type high-efficiency filter, it is necessary to use gaskets, adhesives, negative pressure sealing, liquid filling sealing, and double-ring sealing methods with the frame between the seals. The surface and the liquid tank should be wiped clean, the thickness of the gasket should not exceed 8 meters, the compression rate should be kept between 25% and 30%, and the shape and material of the joint should meet the design requirements.

The above are the precautions for the W-type high-efficiency filter introduced by Xiaobian during the installation process. I hope to provide you with some useful help. If you have any needs in this regard, please feel free to contact us for consultation.