In biopharmaceuticals, in order to ensure the quality of drugs, pharmaceutical factories have higher requirements and regulations on environmental cleanliness and temperature and humidity in the production workshop. In the design of the pharmaceutical workshop, the relevant requirements for the V-type air filter have been put forward. According to the different production conditions, the types of air filters are also very different.

The pharmaceutical purification workshop is different from other industrial purification workshops. The difference is that when producing preparations and raw materials aseptically, not only the suspended particles in the air, but also the number of microorganisms must be controlled. Therefore, the air-conditioning system in the medical workshop should control the microorganisms within the scope of relevant regulations.

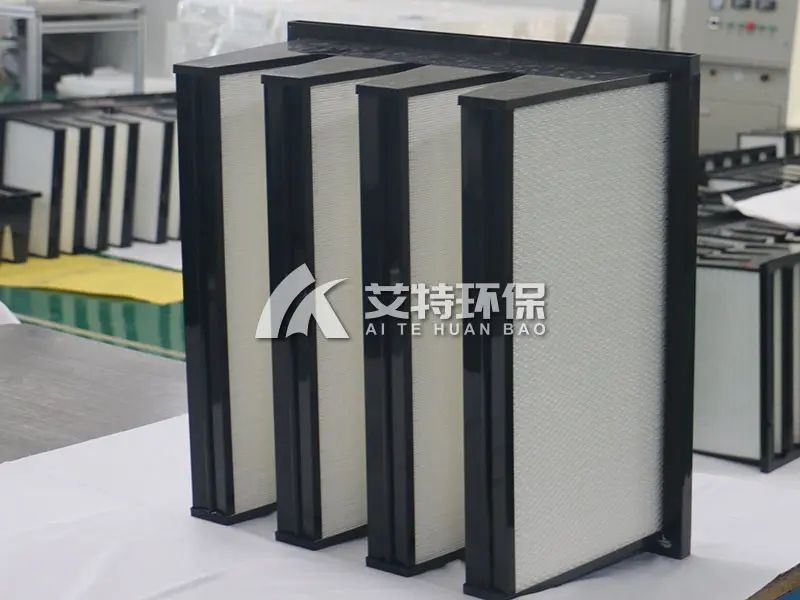

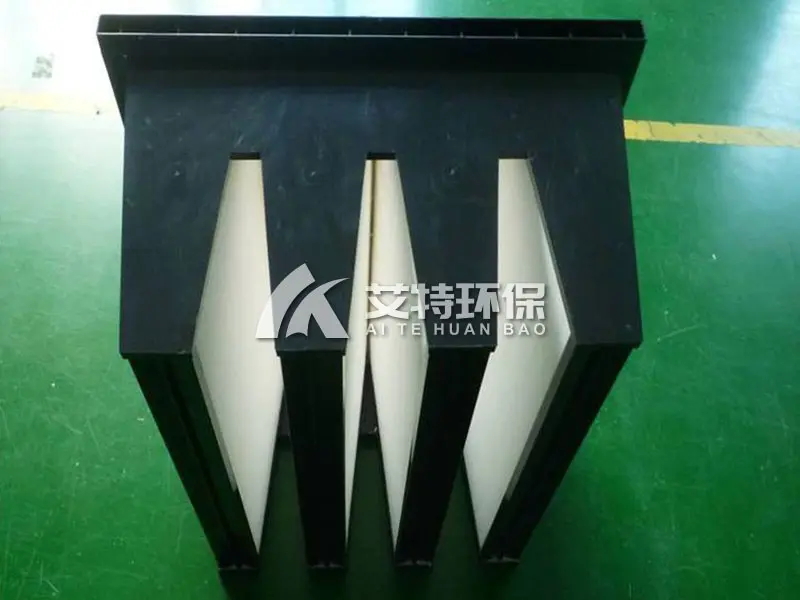

The air filter uses a porous filter material to capture dust from the airflow, purify the air, and purify the dust-containing air into the room to ensure the cleanliness of the air in the indoor room. For demanding pharmaceutical plants, tank filters are usually used for filtration. The liquid tank filter is mainly used to capture particles below 0.3μm, with good sealing performance, high filtration efficiency, low flow resistance, and can be used for a long time to reduce the cost of later consumables and provide clean air for the clean workshop of pharmaceutical companies.

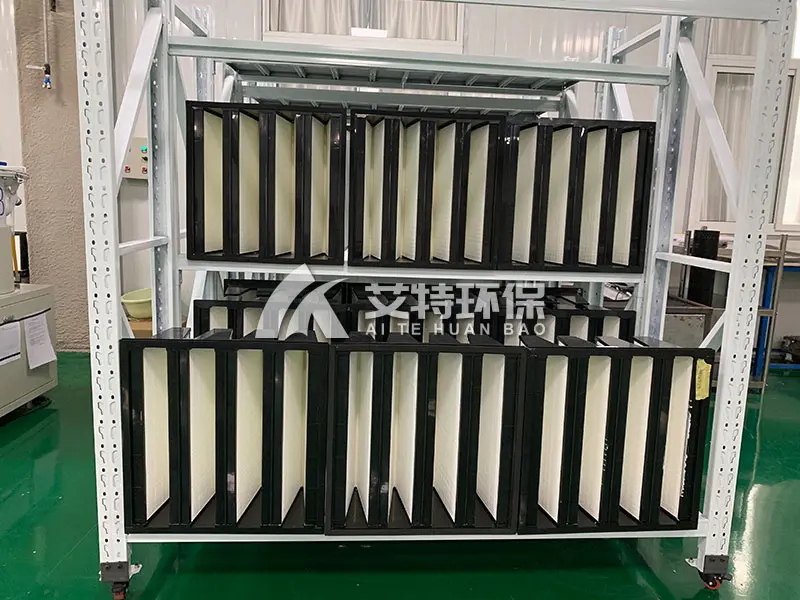

V-type air filters are generally leak-tested before leaving the factory, but non-professional operation requires extra attention during the handling and installation process. For improper installation, the leakage of contaminants from the frame into the clean room also occurs from time to time. Therefore, a leak test is usually carried out after installation to confirm whether the material of the filter is damaged; whether there is leakage in the box; and whether the filter is installed correctly.

In the later use, it should also be checked regularly to ensure that the filtration efficiency of the filter meets the production requirements.