Textile industry security filter element replacement method

In the textile industry, many links need to use security filters, such as textile sewage filtration, textile dye filtration, staff sewage filtration and so on. When the security filter is used in the textile industry, the service life of the filter element is limited, and it needs to be replaced regularly.

First, the common reasons for the replacement of the filter element of the security filter

1. The raw water quality is unstable and fluctuates frequently, resulting in excessive particles in the filter and shortening the cycle;

2. The pretreatment operation effect is poor. The flocculant and scale inhibitor added in the pretreatment are incompatible with each other or with the water source.

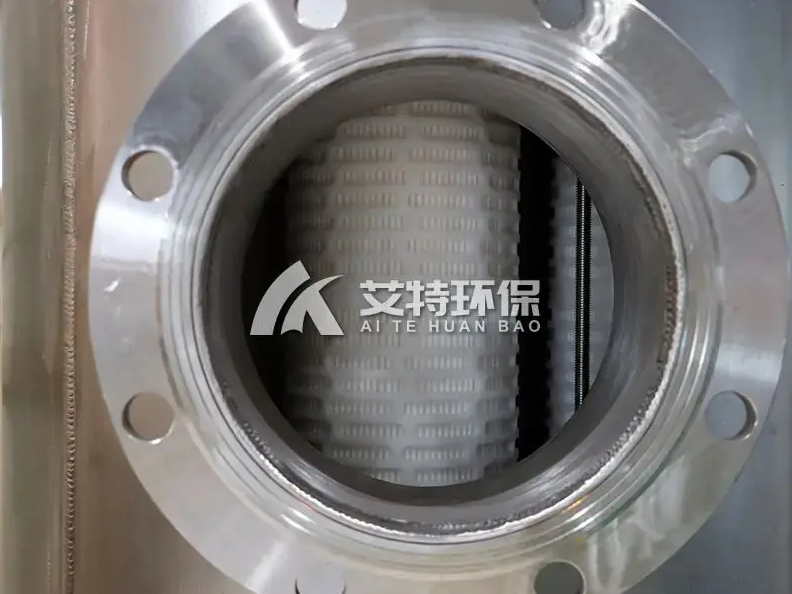

3. The quality of the screen is not good, the quality of the screen aperture is basically the same inside and outside, in fact, only the outer layer plays the role of interception, and a good screen aperture is reduced from the outside, the accuracy of the inner screen is 5±0.5um.

Second, the textile industry security filter element replacement method

1. Close the front and rear valves of the system power supply and security filter;

2. Open the drain pipe and drain out the water in the security filter;

3. Open the upper head and take out the security filter;

4. Wash the inner wall of the security filter;

5. Install security filter and seal the upper head;

6. Seal the discharge port of the security filter and open the front and rear valves of the security filter.

The textile industry for the security filter element is a great demand, especially more than 20 core security filter. Therefore, the filter element needs to be replaced regularly.