Hydac oil filter is a hand-pushed refueling trolley. Hydac oil filter is converted from German Hydac oil filter by Aite environmental protection manufacturer. This hydraulic oil filter inherits various advantages of Hydac oil filter and is more convenient in use.

Hydac oil filter is a hand-pushed refueling trolley. Hydac oil filter is converted from German Hydac oil filter by Aite environmental protection manufacturer. This hydraulic oil filter inherits various advantages of Hydac oil filter and is more convenient in use. This portable hydraulic device can be used for equipment maintenance and filtration of oil and oil filling and emptyof hydraulic equipment. OFU Hydac filter adopts large size filter element, large filter area ensures filtration efficiency and filter element service life. The high performance gear pump ensures the stability of suction, and reduces the impact on the filter element while ensuring the large flow rate, extending the service life of the filter element and even the whole equipment. The filter element of OFU10 oil filter is 1300R series and 2600R series. Replace the filter element should first cut off the power supply, close the inlet and outlet ball valve. Remove the top cover by turning the handle counterclockwise. Pull out the old filter element. Insert the new filter element, press the small red column, and tighten the top cover clockwise. Loosen the exhaust wire plug and start the system. Tighten the exhaust wire plug after the gas is discharged.

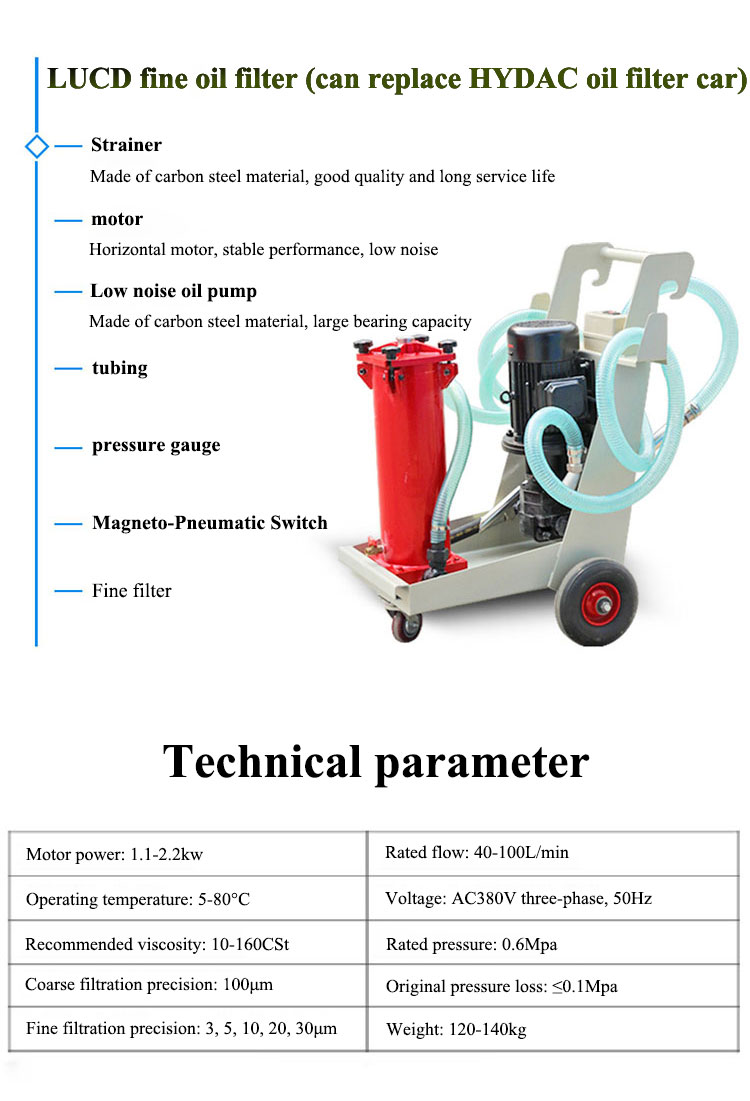

OF5 portable oil filter technical parameters:

1. Model: OF5 Hydac oil filter trolley

2. Features: Low cost oil filter trolley without conversion device

3. Medium: mineral oil, other oil consulting Aite environmental protection customer service hotline

4. Rubber ring: NBR

5. Voltage: Motor voltage 380V

6, oil filter element type filter element specification 330 1300 2600

7. Filter material: filter glass fiber

8. Filtration accuracy :10um

1. The pump cannot be reversed when the oil filter is started, so as not to blow out the shaft seal of the oil suction pump and cause air inhalation;

2. Open the exhaust valve in time during the suction process of the oil filter, and close the exhaust valve in time after draining the air;

3. In the process of oil suction, the sound of the pump becomes louder. If the oil suction is not smooth, please consider whether the coarse filter before the pump is blocked.

4. When the oil filter is applied to a certain extent, the filter element inside will accumulate pollution, the pressure difference increases, and the filtration capacity decreases. When the pressure difference reaches 035Mpa, the filter element needs to be replaced.

(1) Place the machine on a flat ground or in the trunk, carefully check whether the machine is loose, and pay special attention to the connection between the motor and the oil pump must be fastened and concentric.

(2) Connect the power supply correctly and start the oil pump to check whether the rotation direction is correct. Otherwise, replace the phase sequence of the power supply.

(3) Connect the inlet and outlet oil pipes and tighten them. Remind the user to pay attention to the fact that the outlet oil pipe and the outlet oil pipe must be fastened, otherwise, with the increase of pressure, the outlet oil pipe will be washed away, adding unnecessary trouble.

(4) After fixing the inlet and outlet oil pipe, that is, start the motor button, the oil pump starts to work normally, and the oil filtered out through the three stages is the purified oil.

(5) When a barrel (box) of oil is pumped out and another barrel (box) of oil is pumped out, it is necessary to move quickly to avoid the oil pump idling for a long time. If it is too late, it will be shut down and restarted after the oil pipe is connected.

OF5 oil filter

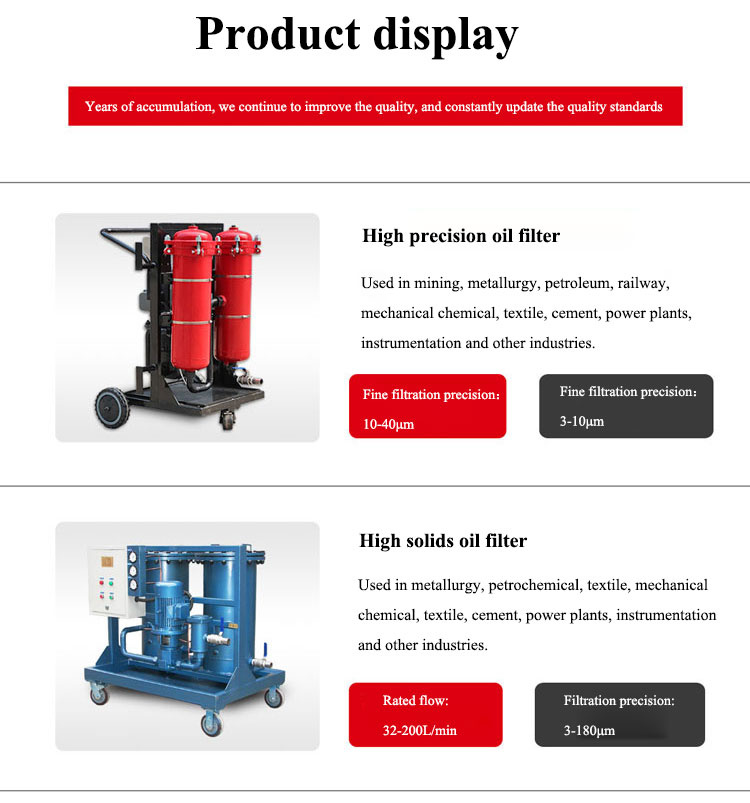

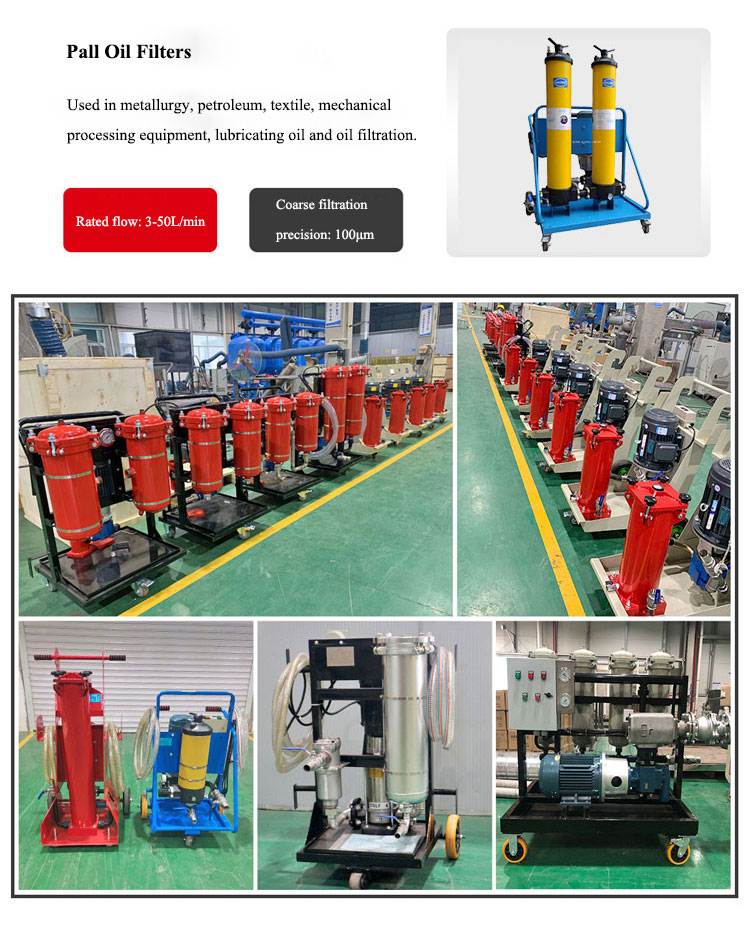

Similar ProductsVIEW MORE >