Hedeco oil filter is produced by Henan Aite Environmental protection filtration Equipment Co., LTD., the manufacturing process is the first peer, after a large number of customers have proved that the oil filter has a long service life and a higher filtering effect,

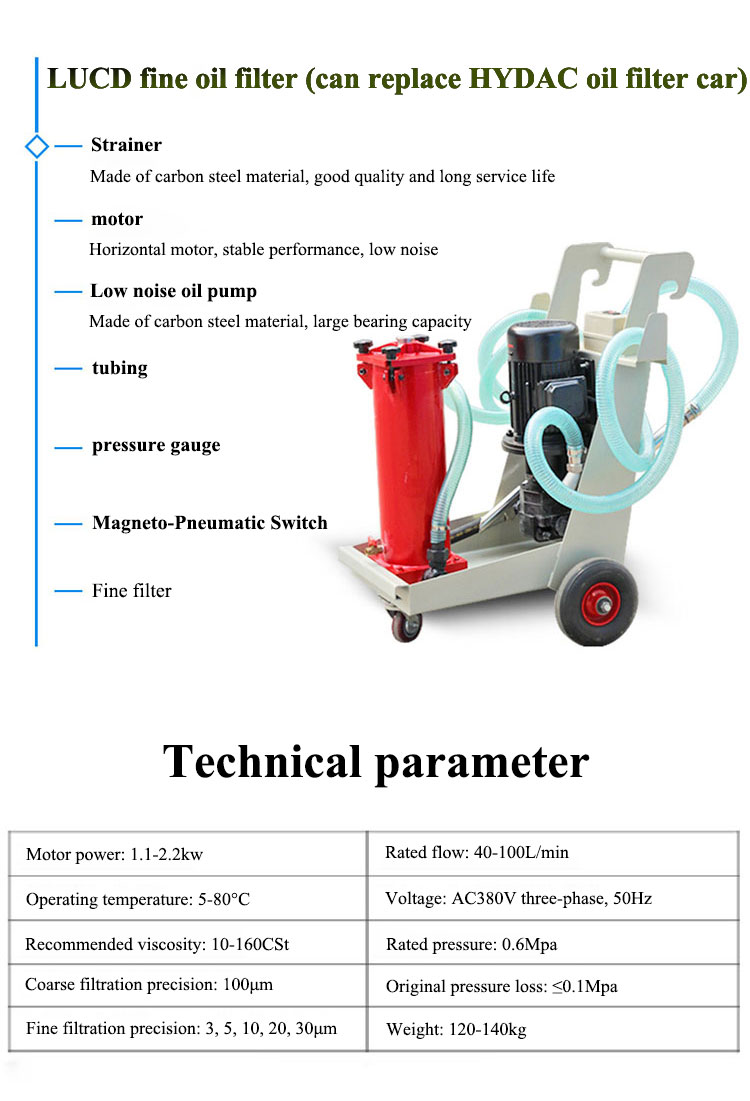

Hedeco oil filter is produced by Henan Aite Environmental protection filtration Equipment Co., LTD., the manufacturing process is the first peer, after a large number of customers have proved that the oil filter has a long service life and a higher filtering effect, Aite environmental protection is the strength of the oil filter manufacturers in Xinxiang region, This mobile oil filter trolley device can be used for simultaneous transmission and filtration of a large amount of oil applications, a large size of the filter element and a high-performance gear pump to ensure effective filtration under the condition of high flow and long service life of the filter element.

High precision, reliable performance, compact structure, beautiful appearance, flexible movement, the use of filter element, precision is 3, 5, 10, 20, 30, 40, 50 microns, users can choose according to need, just replace different precision filter element. The use and maintenance of the oil filter can not be reversed for a long time when starting. Only when the steering is confirmed can it work normally; After the oil filter is used for a period of time, the noise of the oil pump should be increased due to the blockage of the coarse filter element and the fine filter element should be clarified. After the fine filter element is used for a period of time, when the pressure is up to 0.4Mpa due to the blockage of pollutants, the machine should be shut down to clean or replace the fine filter element.

(1) Place the machine on a flat ground or in the trunk, carefully check whether the machine is loose, and pay special attention to the connection between the motor and the oil pump must be fastened and concentric.

(2) Connect the power supply correctly and start the oil pump to check whether the rotation direction is correct. Otherwise, replace the phase sequence of the power supply.

(3) Connect the inlet and outlet oil pipes and tighten them. Remind the user to pay attention to the fact that the outlet oil pipe and the outlet oil pipe must be fastened, otherwise, with the increase of pressure, the outlet oil pipe will be washed away, adding unnecessary trouble.

(4) After fixing the inlet and outlet oil pipe, that is, start the motor button, the oil pump starts to work normally, and the oil filtered out through the three stages is the purified oil.

(5) When a barrel (box) of oil is pumped out and another barrel (box) of oil is pumped out, it is necessary to move quickly to avoid the oil pump idling for a long time. If it is too late, it will be shut down and restarted after the oil pipe is connected.

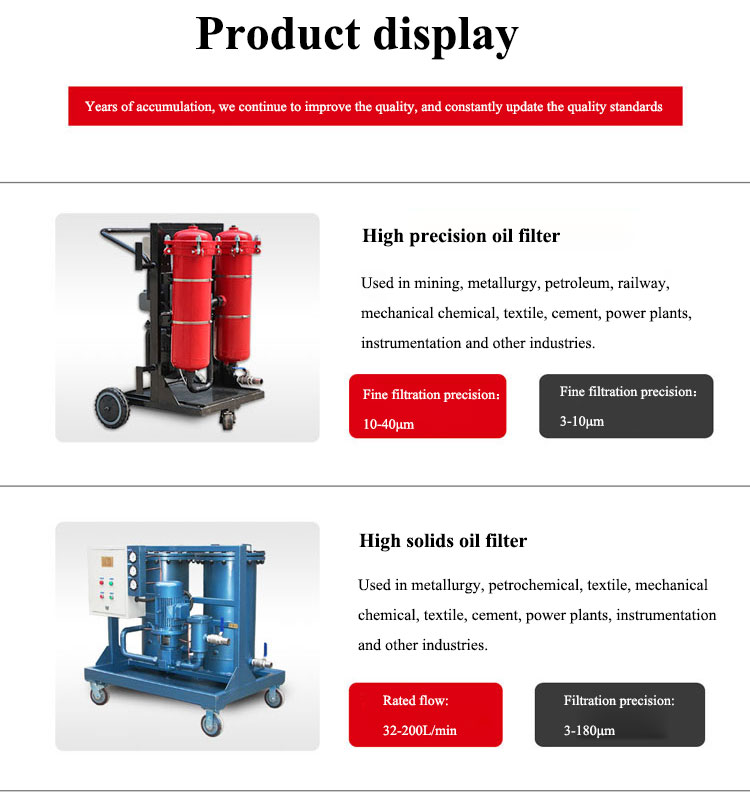

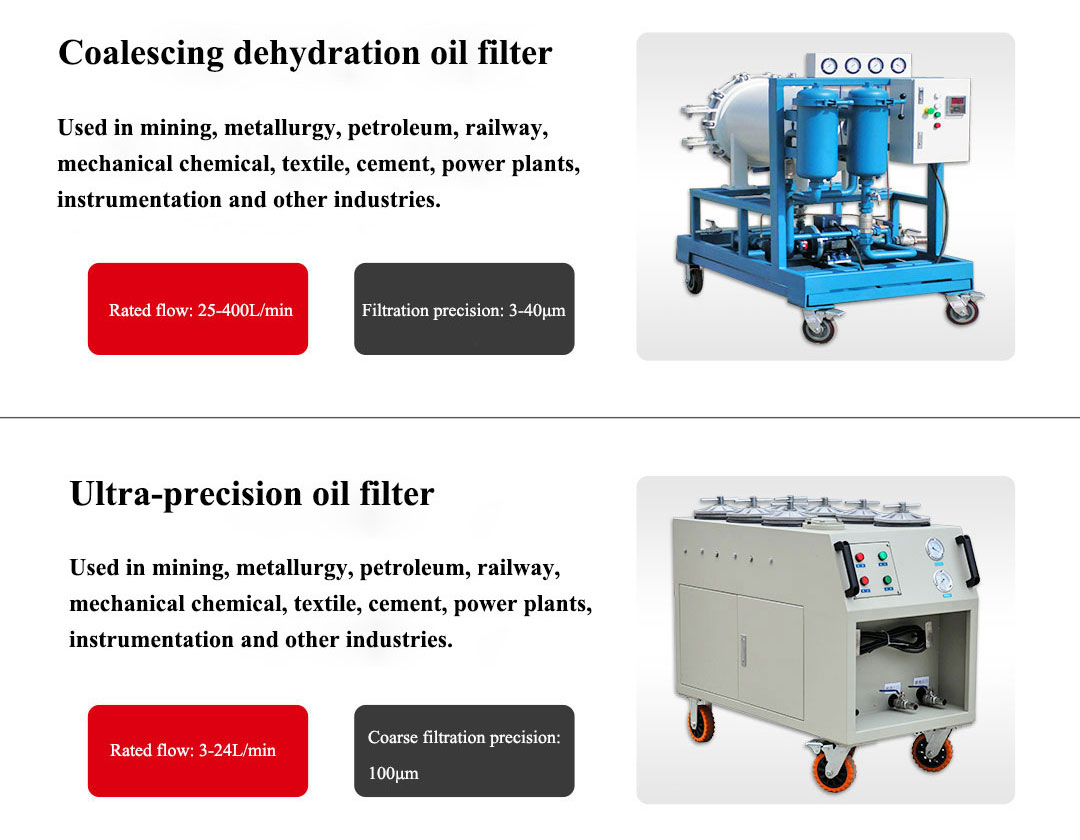

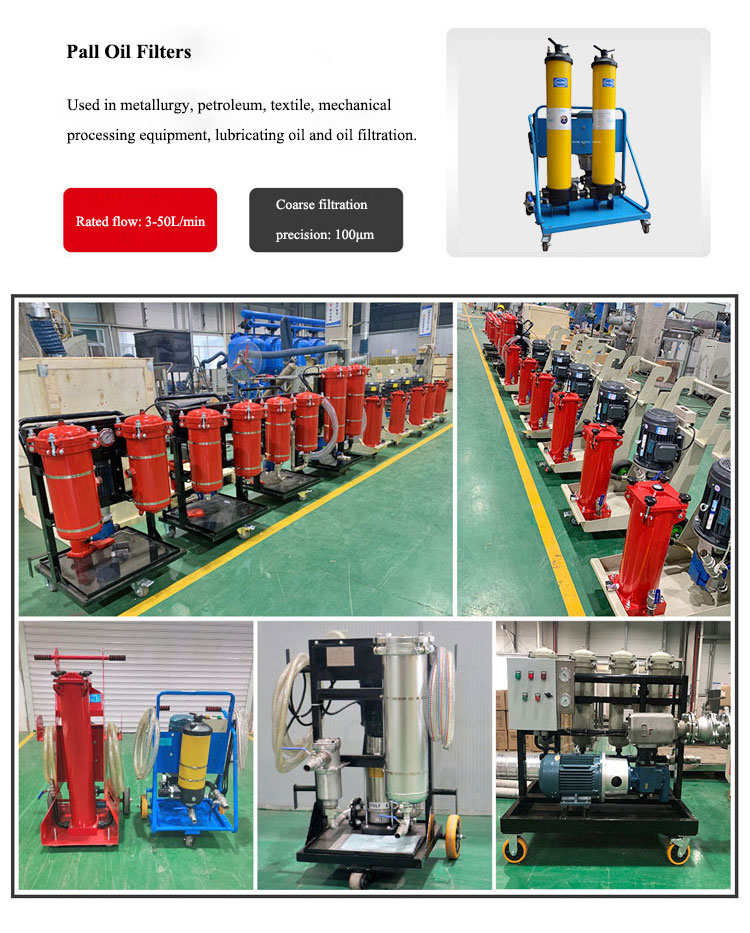

1, metallurgy: used for rolling machine, continuous casting machine hydraulic system filtration and filtration of various lubrication equipment.

2. Petrochemical: separation and recovery of products and intermediate products in the process of refining and chemical production, and particle removal filtration of oilfield injection water and natural gas.

3, textile: polyester melt in the process of drawing purification and uniform filtration, air compressor protection filtration, compressed gas removal of oil and water.

4, electronics and pharmaceutical: reverse osmosis water, deionized water treatment filtration, washing liquid and glucose pretreatment filtration.

OFU100x20 oil filter

Similar ProductsVIEW MORE >