Wet gas drain is aimed at the problem that the gas drain is easy to leak gas. It provides a breakdown-proof and leak-free gas drain, which can be used regardless of gas pressure fluctuation or low water seal (serious water shortage). In all cases, zero leakage of gas can be achieved.

Wet gas drain is aimed at the problem that the gas drain is easy to leak gas. It provides a breakdown-proof and leak-free gas drain, which can be used regardless of gas pressure fluctuation or low water seal (serious water shortage). In all cases, zero leakage of gas can be achieved.

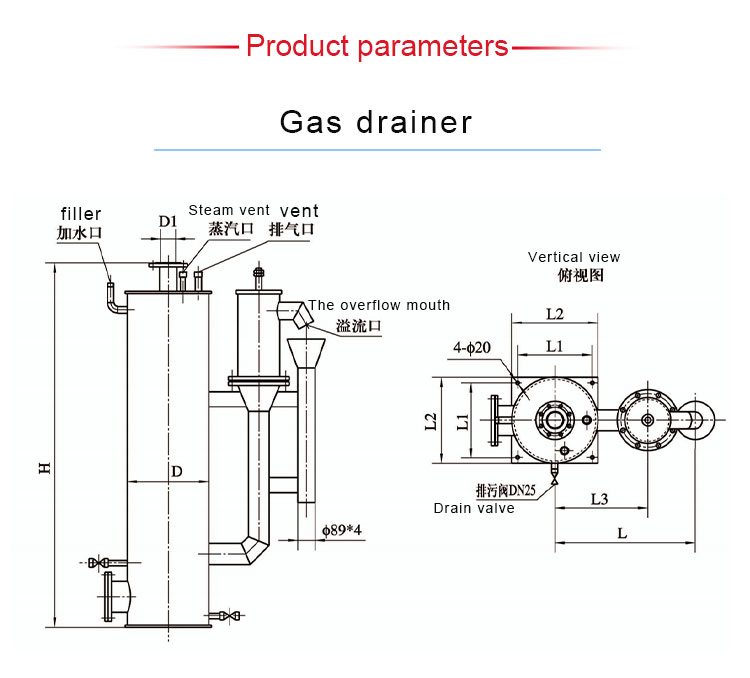

The wet type gas drain is mainly to connect the anti-breakdown non-leakage gas drain into the pipeline for conveying gas. The condensed water in the gas pipeline enters the high pressure chamber of the drain through the drain pipe, and then enters through the connecting pipeline of the high and low pressure chambers on the clapboard. The low pressure chamber of the drainer collects the condensed water and automatically discharges the condensed water in the gas pipeline through the water seal to ensure the normal operation of the equipment. When the gas pipe network pressure fluctuates or the water level of the drainer is abnormally low due to gas breakdown, under the action of the gas shock, the anti-leakage device is triggered to close the overflow port to prevent the gas from leaking out and ensure the normal operation of the equipment.

1. The drain must have a reliable foundation, and the installation must be stable.

2. The drain should not be directly connected to the gas main pipe vertically. Prevent the thermal expansion and contraction and settlement of the connecting pipe and the drain from generating additional load on the gas main. The connecting pipe should have a corresponding inclination and camber, and the angle between the turning flat pipe and the horizontal line should be greater than 30°. For connecting pipes with a height greater than 5m, they should have their own fixing points, and stainless steel corrugated expansion joints can be considered to absorb the expansion.

3. There should be two valves between the gas main and the water seal. The above valve is used as maintenance and emergency valve. The next valve acts as the operating valve.

4. On the connecting pipe, 200mm above the top of the water seal, set up a detection valve. Used to detect whether the drain is blocked.

5. The high pressure chamber of the double water seal must have a vent cock.

6. The drain pipe of the drain should be disconnected, and the water should be drained through the funnel. Direct insertion of drain hoses into drains is not permitted.

7. There should be a water supply pipe on the water seal, which is used as a water supply for the water seal. If the water supply pipe in the water seal is inserted underwater, the water supply pipe should be disconnected from the water supply pipe, and water should be supplied through the open funnel. It is forbidden to connect the water supply pipe directly to the gas chamber under pressure. In order to avoid the occurrence of negative pressure in the water supply pipe, the gas is poured into the water supply pipe. It is forbidden to supply water to the water seal by means of long running water.

8. If the coke oven gas drain needs steam to melt tar, the steam pipe on the drain should be disconnected from the steam main pipe. When in use, reconnect the tube.

9. In places where the temperature is lower than 0°C for a long time in winter, the design of steam heating or electric heating device for the water seal should be considered to prevent the water seal from freezing.

Wet Gas Drain

Similar ProductsVIEW MORE >