Wet gas drainer is aimed at the problem that the gas drainer used is easy to leak gas. It provides a kind of gas drainer with no breakdown and no leakage. It can realize zero gas leakage regardless of the gas pressure fluctuation or the water seal is too low (severe water shortage) under the condition of use.

Wet gas drainer is aimed at the problem that the gas drainer used is easy to leak gas. It provides a kind of gas drainer with no breakdown and no leakage. It can realize zero gas leakage regardless of the gas pressure fluctuation or the water seal is too low (severe water shortage) under the condition of use.

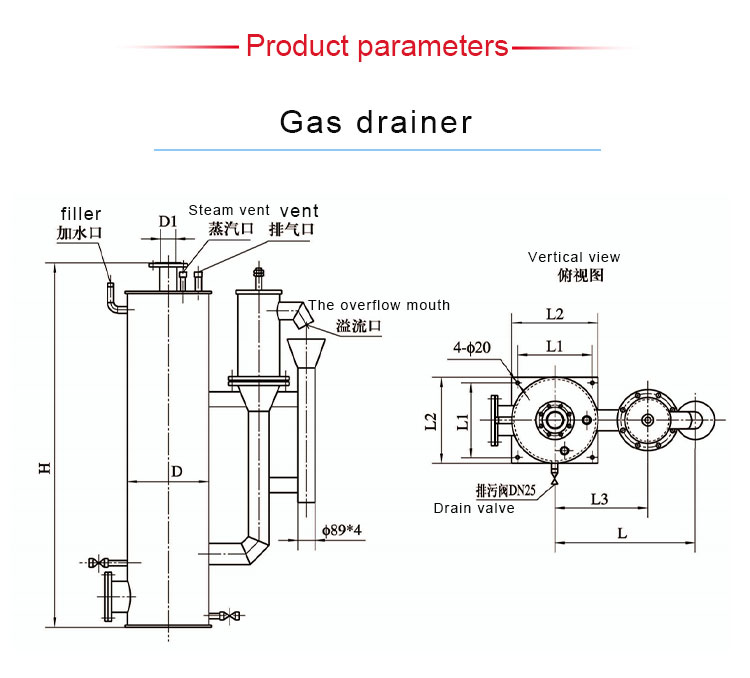

The wet gas drainer mainly connects the non-breakdown and non-leakage gas drainer into the gas conveying pipeline. The condensate water in the gas pipeline enters the high pressure chamber of the drainer through the drain pipe, and then enters the low pressure chamber of the drainer through the connected pipe of the high and low pressure chamber on the partition board. The condensate water is collected and automatically discharged from the gas pipeline through the water seal to ensure the normal operation of the equipment. When the abnormally low water level of the drainer caused by the pressure fluctuation of the gas pipe network or other reasons is broken down by the gas, under the action of the gas impact, the anti-leakage device is triggered to close the overflow port, prevent the gas from leaking out, and ensure the normal operation of the equipment.

1. The drainer should have a reliable foundation and be installed firmly.

2. The drainer should not be directly connected to the gas main vertically. Prevent the expansion, contraction and settlement of the connecting pipe and drainer from causing extra load to the gas main. The connecting pipe shall have a corresponding incline bend, and the Angle between the turning flat pipe and the horizontal line shall be greater than 30°. For the connecting pipe with a height greater than 5m, it should have its own fixed point, and the corrugated expansion joint of stainless steel can be considered to absorb the expansion amount.

3. There should be two valves between the gas main and the water seal. The upper valve is used as maintenance and emergency valve. The next valve serves as the operating valve.

4. Set up a test valve on the connecting pipe at a place more than 200mm above the top of the water seal. Used to detect whether the drain is blocked.

5. The high-pressure chamber of compound water seal should have a cyclone plug.

6. The drain pipe of the drainer should be disconnected and discharged through the funnel. Do not directly insert the drain pipe into the drain.

7. There should be water refill pipe on the water seal for water refill. If the water filling pipe in the water seal is inserted underwater, the water filling pipe and the water supply pipe should be disconnected, and the water should be fed through an open funnel. It is forbidden to connect the feed pipe directly to the gas chamber under pressure. In order to avoid negative pressure in the water supply pipe, the gas is poured back into the water supply pipe. Do not refill water seal with long running water.

8. If the coke oven gas drainer needs steam to melt tar, the steam pipe on the drainer should be disconnected from the steam master pipe when it is flat. When in use, connect the pipe again.

9. Where the temperature is lower than 0℃ for a long time in winter, steam heating or electric heating devices should be designed for water seals to prevent them from freezing.

Wet gas drainer

Similar ProductsVIEW MORE >