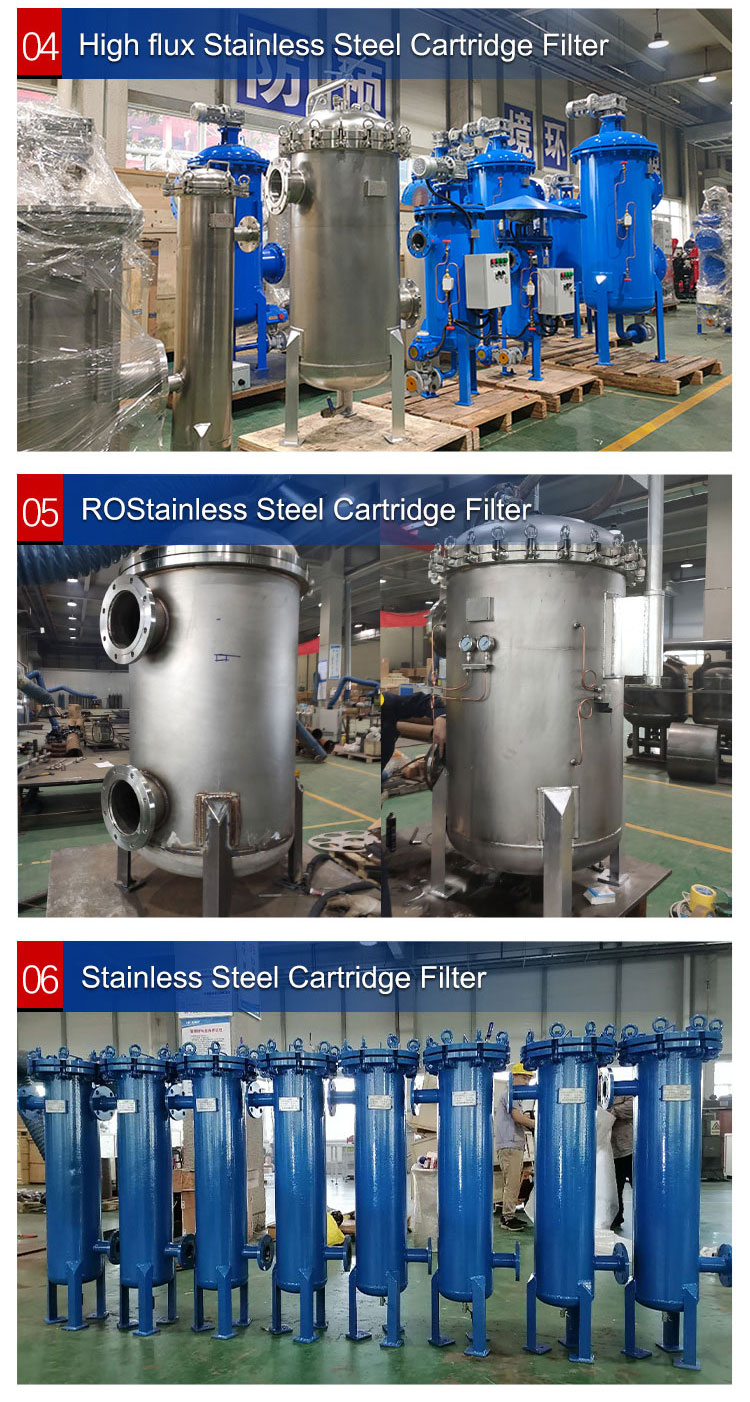

Aite environmental protection large flux security filter weld with automatic welding technology, the weld is strong and beautiful, the equipment cover structure adopts a unique design of quick opening flange, can be convenient and quick to open, lock equipment, maintenance, replacement of filter element is very convenient.

Aite environmental protection large flux security filter weld with automatic welding technology, the weld is strong and beautiful, the equipment cover structure adopts a unique design of quick opening flange, can be convenient and quick to open, lock equipment, maintenance, replacement of filter element is very convenient. The equipment has a high strength stainless steel tubular support guide bar connected with the bottom plate. When installing the filter element, it can be easily and quickly loaded along the supporting guide bar and effectively support and protect the filter element. The base of the sealing filter element is machined by precision numerical control and has a taper, which can guide the sealing ring of the filter element to cooperate closely with the base and prevent any material leakage. The filtration accuracy of 1 micron can guarantee the filtration efficiency of 99.9%.

The vertical structure can minimize the footprint of the filtration system, while the horizontal structure can simplify installation and operation to a large extent. According to the actual demand, arbitrary choice of vertical or horizontal structure.

1. can remove 0.01micron and above particles;

2. effective continuous removal of oil mist more than 99.99% oil mist concentration control below 0.01ppm;

3. large filter area, small pressure loss, easy to replace the filter element;

4. stable filtration performance, compressed air can be used continuously;

5. with pressure difference indicating device;

6. automatic blowdown and manual blowdown two ways;

7. long service life.

Filter material: SS304, 316L, carbon steel

Seal form: O-ring seal

Equipment opening: quick opening flange cover opening

Replacement pressure difference: 2.0bar

Maximum pressure difference: 2.4bar

Maximum flow: 350 gal/min (1325 L/min) 40"

Maximum temperature: 90℃

Seal type: O-ring seal

Surface treatment: matte spray bead

Filtration accuracy: 1, 3, 5, 10, 20, 30, 50, 70, 100um, etc

1. Petrochemical, chemical industry: hydrogen peroxide, resin, lubricating oil, polymer, viscose, jet fuel and all kinds of oil, catalyst, chemical fiber manufacturing process of all kinds of fluid purification, chemical intermediate products and chemical products separation and recovery;

2. Oil and natural gas industry: CNG filtration in gas station, amine desulfurization and dehydrating agent filtration, separation and purification of natural gas and refinery, oilfield water injection, workover, acidizing liquid filtration;

3. Coating, paint, ink industry: latex paint, paint raw materials and solvent filtration, printing ink, printing ink and additives;

4. Pharmaceutical and biological engineering industries: infusion (LVP and SVP) pharmaceutical water, biological products plasma serum, various pharmaceutical intermediates, pharmaceutical raw materials, solvent filtration, CIP filtration, fermenting tank intake and tail gas sterilization filtration;

5. Automobile manufacturing industry: electrophoretic paint, top paint, ultrafiltration water, pre-treatment liquid, vehicle spray water, engine crankshaft manufacturing coolant, spray paint industrial gas and spray paint room gas purification;

High throughput security filter

Similar ProductsVIEW MORE >