The self-cleaning air filter ATZK-2100 is made of laser cutting, CNC machine tool processing, mold welding, modular manufacturing, electrostatic spraying, and building block assembly.

The self-cleaning air filter ATZK-2100 is made of laser cutting, CNC machine tool processing, mold welding, modular manufacturing, electrostatic spraying, and building block assembly.

1. According to the user's requirements, this product can be equipped with a dust collecting box, dustproof net, and water washing and dust removal method to solve the secondary pollution.

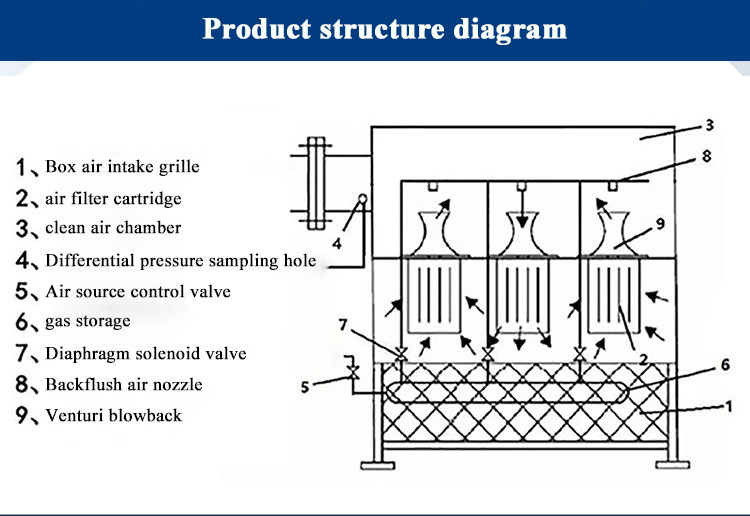

2. The device is controlled by an intelligent distributor, and there are three self-cleaning methods, namely (1) timing; (2) differential pressure; (3) manual.

3. This equipment can realize automatic cleaning of air filter elements, so that the equipment can operate as usual without affecting the normal operation of other filter elements.

4. It can work normally under the condition of high relative humidity.

5. The filter area is large, the flow rate is low, the resistance loss is small, and there is a liquid crystal display resistance loss.

6. The filter element has a long service life. Under normal environmental conditions, the filter element replacement cycle can reach about 2 years.

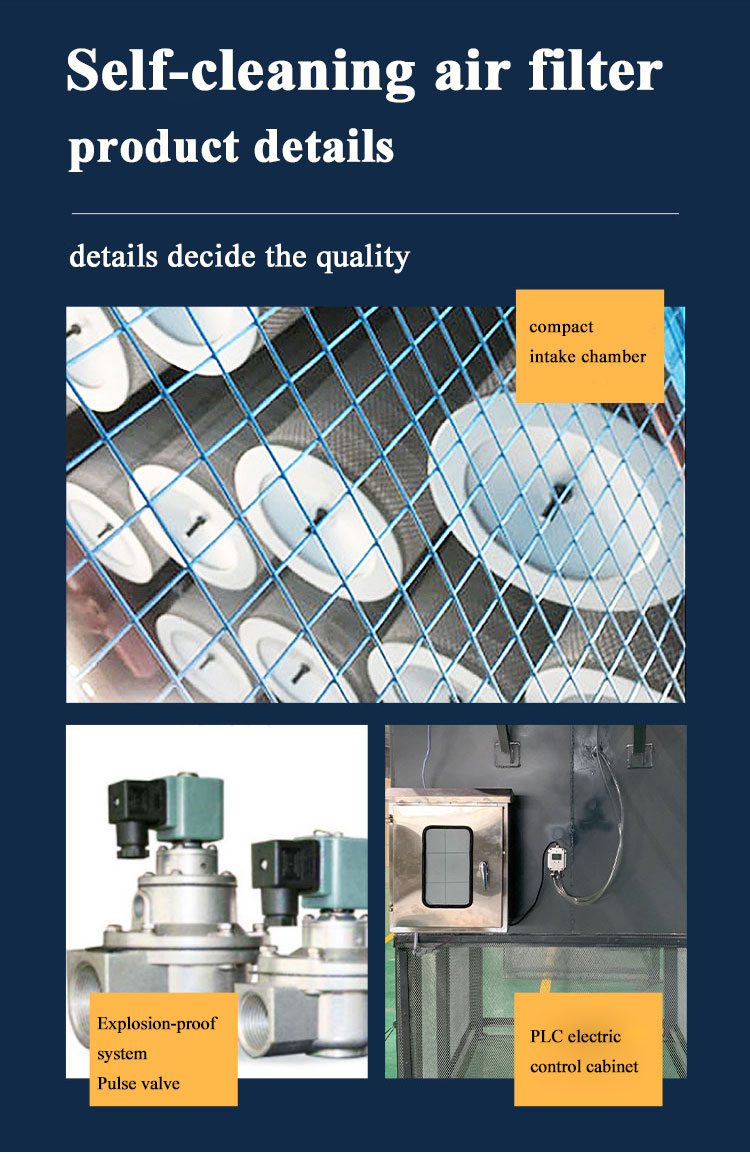

7. The degree of automation is high, and the main components are imported, which can realize unmanned operation.

1. Various types of compressed air stations in various industries;

2. Blast furnace blower in steel plant;

3. The raw material air machine of the oxygen station;

4. Gas turbines of various capacities;

5. Diesel engines that need to run for a long time;

6. Air conditioning and air supply system for chemical fiber textile industry;

7. Centralized air-conditioning systems that require high air cleanliness (for example: computer rooms, pharmaceutical industry, food industry, etc.).

Self-cleaning air filter ATZK-2100

Similar ProductsVIEW MORE >