Self-cleaning pulse air filter has the advantages of small volume, high efficiency, low investment, easy maintenance and so on. But because of its small equipment capacity, it is difficult to combine into large air volume equipment, low filtering wind speed, narrow application range, only in food, welding and other industries, so it has not been widely promoted over the years.

Self-cleaning pulse air filter has the advantages of small volume, high efficiency, low investment, easy maintenance and so on. But because of its small equipment capacity, it is difficult to combine into large air volume equipment, low filtering wind speed, narrow application range, only in food, welding and other industries, so it has not been widely promoted over the years. In recent years, with the continuous development of new technology and new materials, the company represented by Japan and the United States has improved the structure and filter material of the dust collector, which makes the filter barrel dust collector widely used in cement, steel, electric power, food, metallurgy, chemical and other industrial fields.

Number of filter cylinders: 16

Initial resistance: ≤150Pa

Power consumption: 100W

Back blowing air: 0.1m3/min

Blowback pressure: 0.4-0.6MPa

Noise: < 80dB

Filtration accuracy: 1 micron

Cleaning method: pulse cleaning

Shell material: Q235

Steel plate thickness: 3mm

Wenshi tube material: engineering plastic

Installation: outdoor vertical

1, this product can be according to user requirements at the bottom of the dust collection box, air filter, water cleaning dust removal method to solve the secondary pollution.

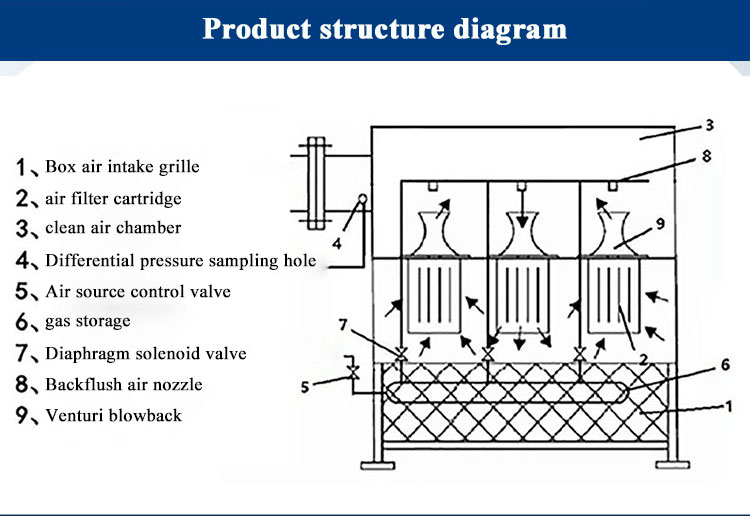

2. The device is controlled by the intelligent distributor, and there are three self-cleaning methods, namely (1) timing; (2) pressure difference; (3) Manual.

3, the equipment can realize the automatic cleaning of the air filter element, so that the equipment runs as usual, without affecting the normal work of other filter elements.

4. It can work normally under the condition of relative humidity ****.

5, the filter area is large, the flow rate is low, the resistance loss is small, and the liquid crystal display resistance loss.

6, filter element long service life. Under normal environmental conditions, the replacement cycle of the filter element can reach about 2 years.

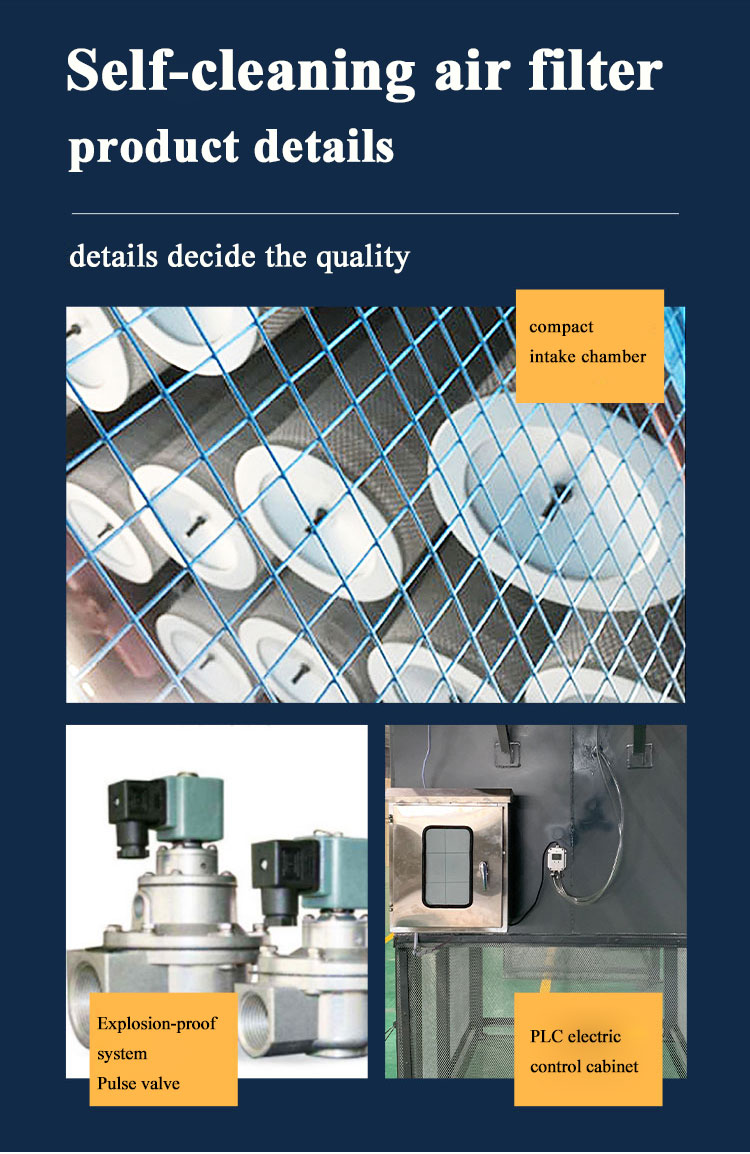

7, high degree of automation, the main components are imported parts, can realize unmanned operation.

8, back blowing gas consumption is small, generally 0.1 ~ 0.3m3/min(inhalation state); The pressure is 0.4 ~ 0.6Mpa.

9, the weight of the equipment is light, is the same capacity of cloth bag 1/3-1/2.

10, reasonable design, no bend design, high-rise block type combination, easy to install, fast.

11, this product has special requirements, the company can carry out non-standard design according to customer requirements, to meet customer needs.

1. Blast furnace induced draft fan of iron and steel plant;

2. Compressor inlet of oxygen producing device;

3. Gas turbines and diesel engines of various capacities;

4. Air conditioning supply system for chemical fiber textile and electronics industry;

5. Centralized air conditioning system with high requirements for air dust content;

6. Air conditioning supply system for tobacco and paper industry.

Self-cleaning pulsed air filter

Similar ProductsVIEW MORE >