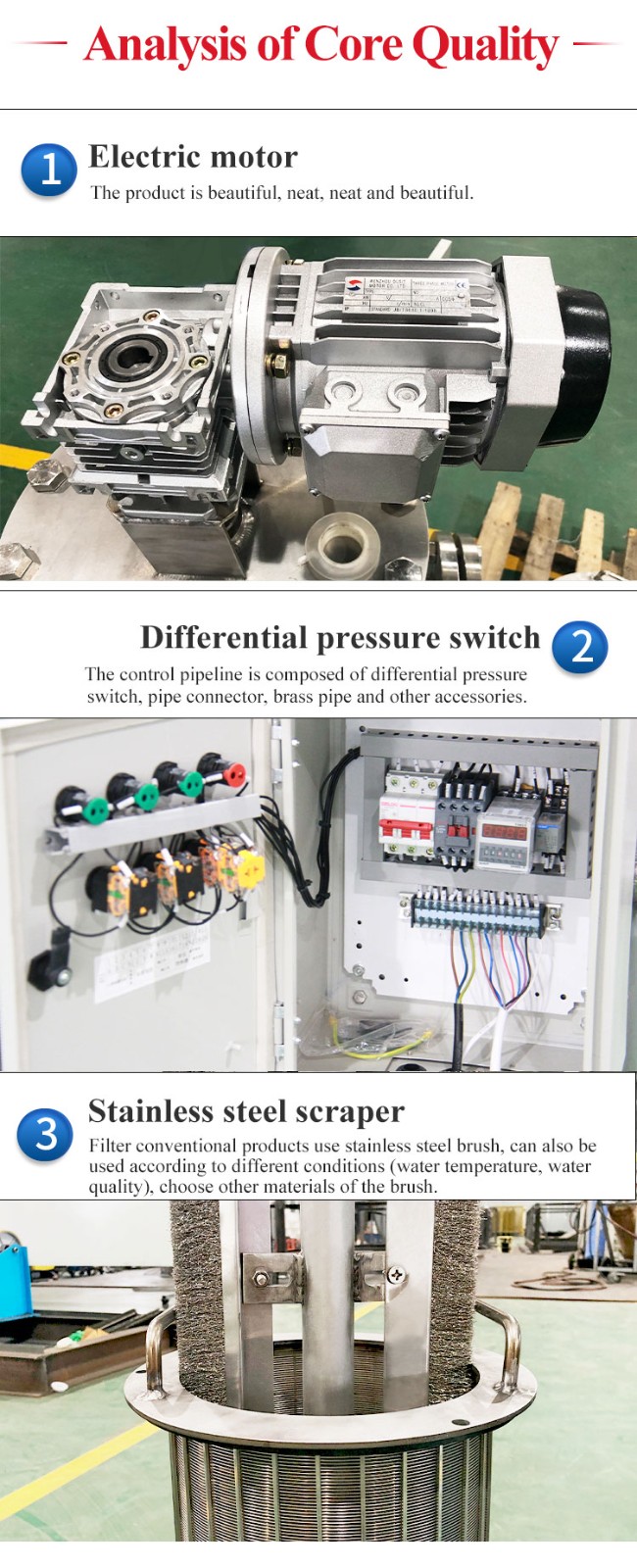

The whole self-cleaning process of the electric brush filter consists of two steps: opening the automatic blowdown valve located on the self-cleaning filter; The motor drives the cleaning system in the filter screen, and the impurities intercepted by the filter screen are discharged from the blowdown valve.

The whole self-cleaning process of Electric brush type self-cleaning filter consists of two steps: opening the automatic blowdown valve located on the self-cleaning filter; The motor drives the cleaning system in the filter screen, and the impurities intercepted by the filter screen are discharged from the blowdown valve. The system does not interrupt the flow when cleaning, and the whole operation process of the self-cleaning filter is controlled by an intelligent control box randomly equipped. Control mode optional pressure difference, time, manual and PLC control.

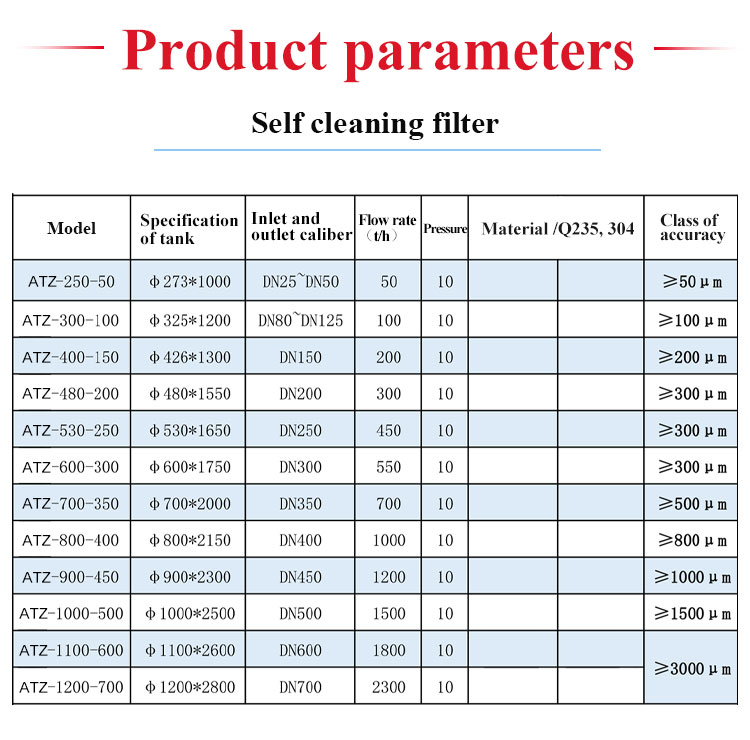

The maximum filtering flow of a single machine can reach 5000T/H

Filtration accuracy from 4000 microns to 10 microns

Filter optional drilling (4000-800μm), wedge (1000-50μm) braided composite (800-20 μm)

Minimum working pressure ≥0.1MPa

Maximum working pressure ≤1.6MPa(special can be customized)

Operating temperature ≤95℃

Power supply: 380V/50Hz

Cleaning motor power: 0.09-1.5KW

Cleaning method: Brush type

Minimum cleaning water: 50 L

Control mode: pressure difference, time, manual and man-machine interface (PLC)

Cleaning time: Adjustable from 10-200 seconds

Blowdown valve diameter: DN40 -- DN80

When selecting the electric brush type self-cleaning filter, the following parameters need to be considered

1. Process traffic

2. Chemical properties of filter media

3. Concentration of suspended matter in filtration medium

4. Required filtration accuracy

5. Pipeline pressure

Electric brush type self-cleaning filter

Similar ProductsVIEW MORE >