Automatic backwash filter is mainly composed of simplified, stainless steel filter, electric blowdown valve and blowdown device

Automatic backwash filter is mainly composed of simplified, stainless steel filter, electric blowdown valve and blowdown device. When the water filter is working, the backwash butterfly valve plate is opened, and the water flow enters the filter element from the inlet and flows out of the system after filtering through the filter screen, and the impurities are intercepted in the filter element. When the water processor needs to blow down, close the butterfly valve plate, open the blowdown valve, water flow through the filter screen in the second half of the outside into the inside, through the first half of the filter, part of the water flow into the system from the outlet, the remaining water flow from the filter screen in the second half of the outside into the inside, through the sewage discharge outlet, play the role of automatic reverse washing filter screen.

Under normal circumstances, the steering valve is opened, and the water flow is filtered through the filter barrel and discharged from the outlet. When the sewage valve station is opened, the total flow rate of the filtered liquid increases and the velocity increases, which impedes the impurities stuck on the wall of the filter pipe and the impurities are discharged from the sewage outlet. When the steering valve is closed and the sewage valve is opened, the water flow is forced to enter the outside of the filter barrel through the mesh of the inlet section of the filter barrel. Most of them flow out from the outlet, and some of them enter the filter cylinder from the outside of the filter through the mesh of the impurity collection section, resulting in backwashing of the filter cylinder, so as to achieve the effect of washing the impurities adhering to the mesh from the outside of the filter cylinder, and the impurities are still discharged through the sewage outlet.

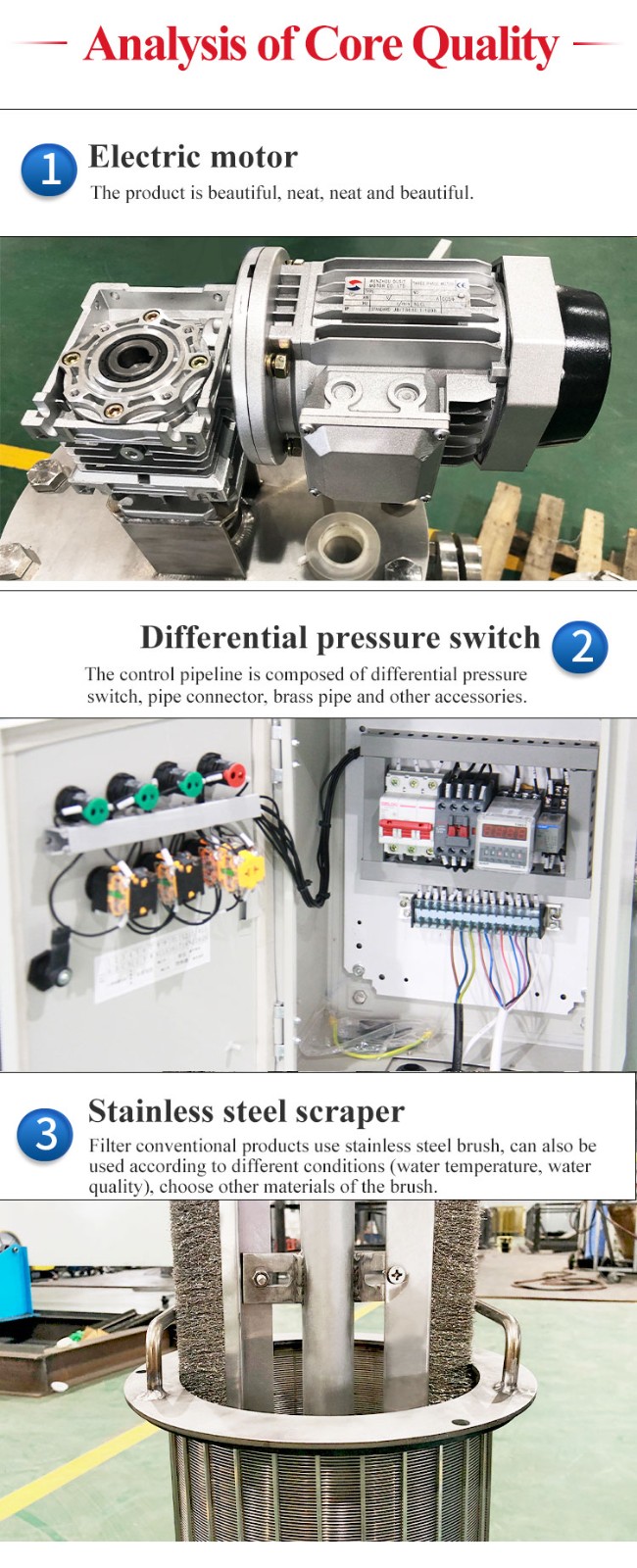

Shell: Carbon steel, 304 stainless steel, 316L stainless steel

Screen: 304 stainless steel, 316L stainless steel

Brush holder: 304 stainless steel, 316L stainless steel

Blowdown valve: cast iron, stainless steel

Controller: Copper

Sealing ring: PTFE

1. Automatic backwash system

From the inside out, forward filtration, reverse backwashing modular design, multi-core structure, large filtering area, large amount of pollution, can cope with unstable water fluctuations, automatic backwashing function.

2. Automatic control system

Intelligent control system responsive, accurate operation, facial cleaning intuitive and easy to operate.

3. high performance precision filter element

V-shaped gap precision filter element: V-shaped opening backwash effect is good, good at applying to micro filtration, sludge, soft caking and other difficult backwash pollutants and impurities filtration.

4. Advantages of overall architecture

The whole equipment structure has no consumables, less wearing parts, low operating cost, food grade design, jacket explosion-proof design, perfect filtration of flammable and explosive liquid.

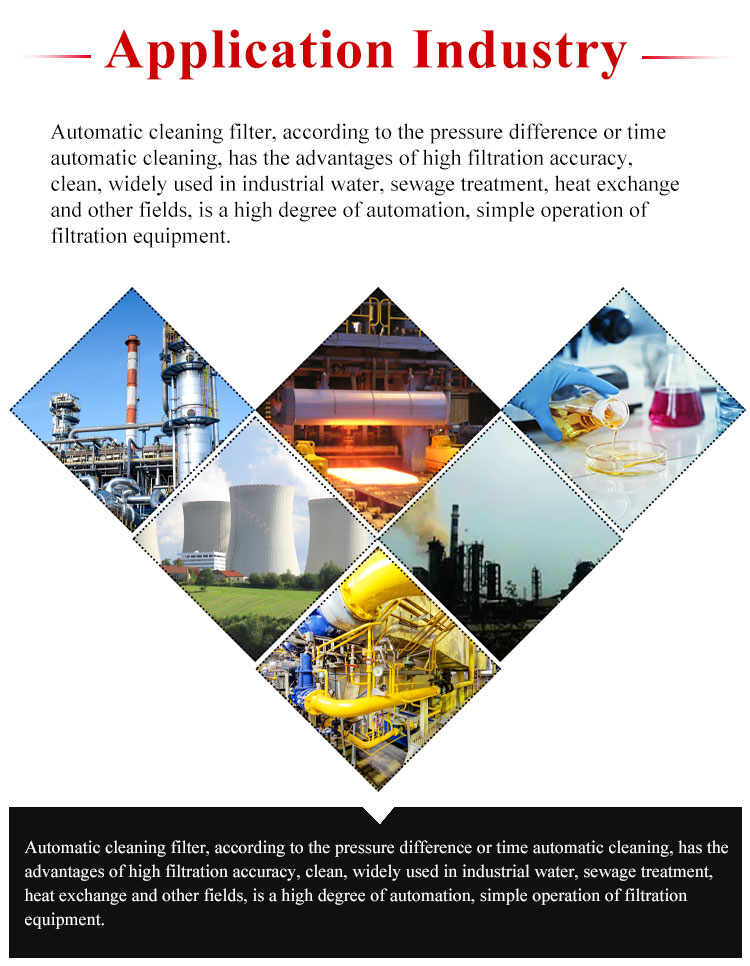

Remove all kinds of viscous substances, colloidal particles, silt and other mechanical impurities in the water.

Heating system in heating, heating hot water circulation system; Central air conditioning, water chillers, chillers cooling and freezing circulating water system; Industrial and civil cooling water, industrial cooling circulating water system; The use of geothermal water for bathing, heating circulation system.

Backwash filter

Similar ProductsVIEW MORE >