Scraper-type self-cleaning filter is a kind of filter that directly intercepts impurities in water, removes suspended solids and particulate matter in water body, reduces turbidity, purifies water quality, reduces system fouling, algae, rust, etc., to purify water quality and protect other systems.

Scraper-type self-cleaning filter is a kind of filter that directly intercepts impurities in water, removes suspended solids and particulate matter in water body, reduces turbidity, purifies water quality, reduces system fouling, algae, rust, etc., to purify water quality and protect other systems. When the equipment is working normally, the water enters the self-cleaning filter body from the water inlet. Due to the intelligent (PLC, PAC) design, the system can automatically identify the degree of impurity deposition and automatically discharge the sewage through the signal of the blowdown valve.

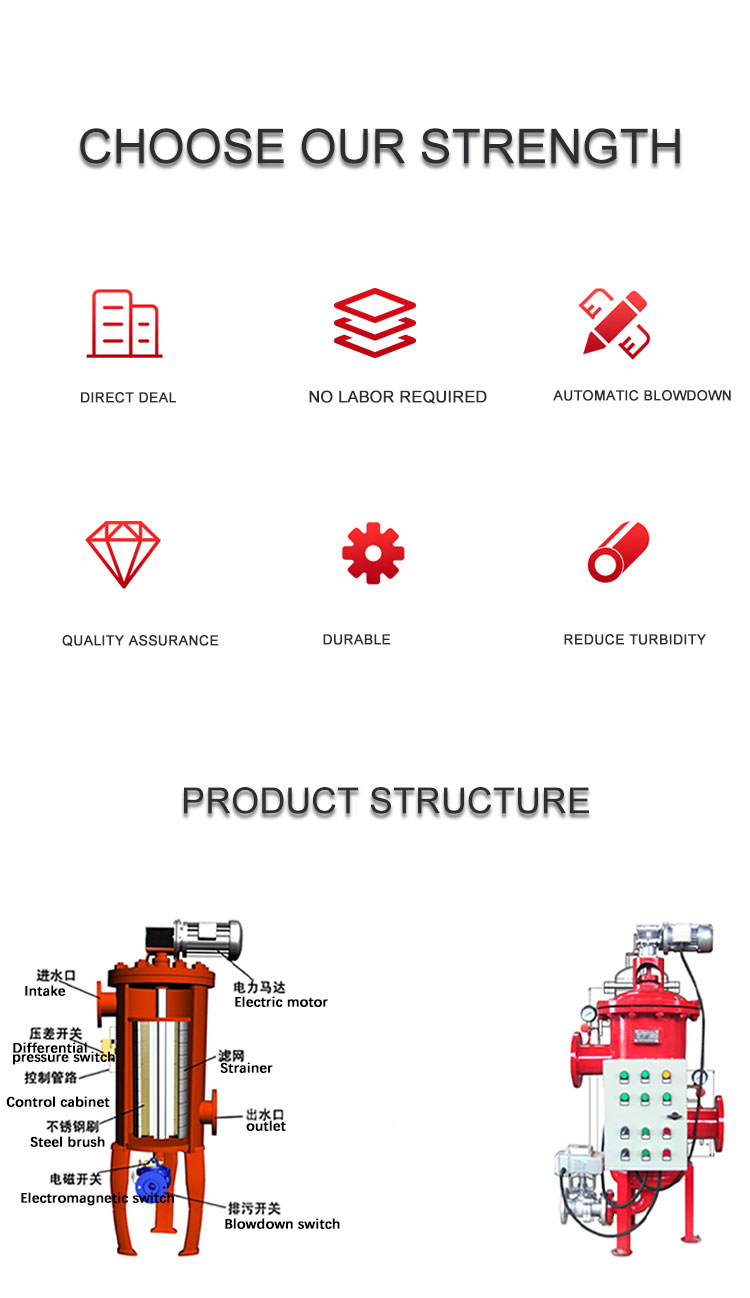

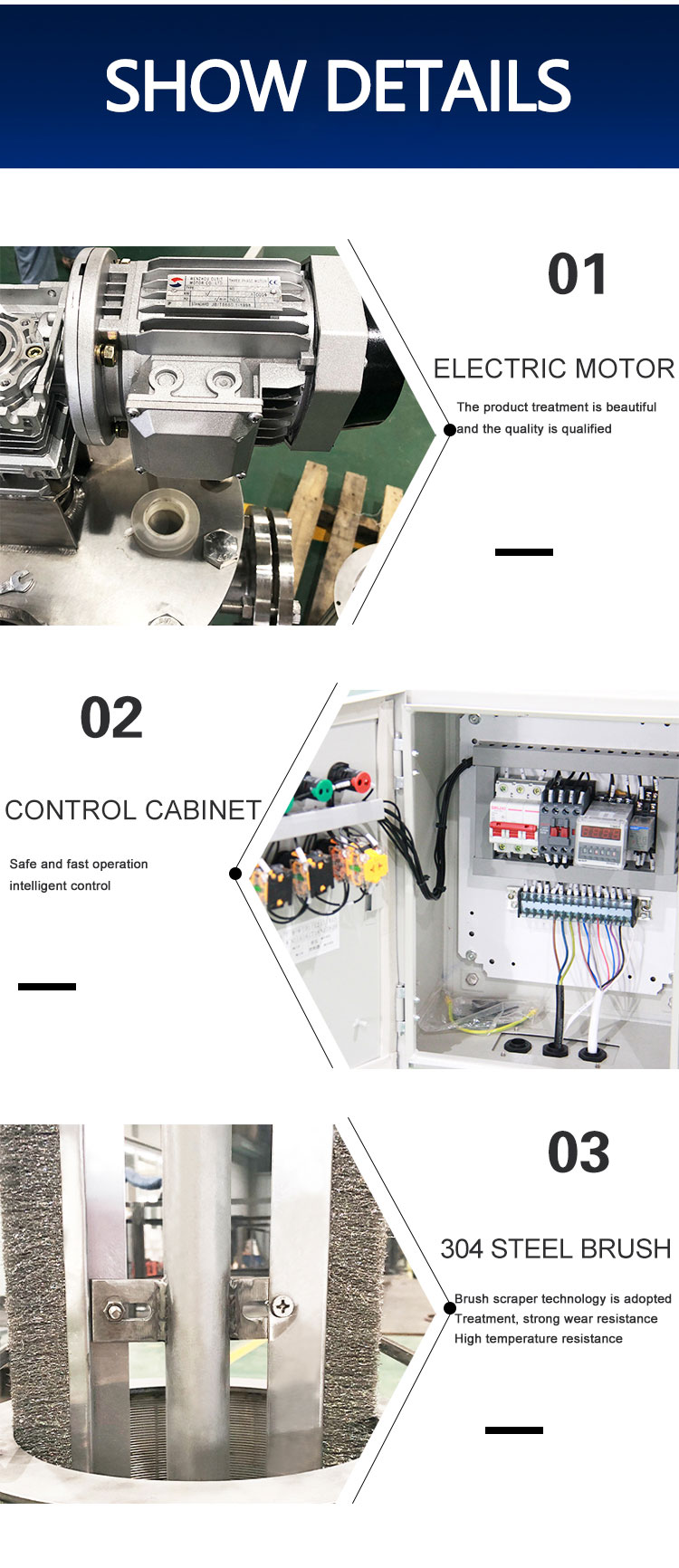

The water enters from the inlet, firstly passes through the coarse filter to filter out larger particles of impurities, and then reaches the fine filter. During the filtration process, the fine filter gradually accumulates dirt and impurities in the water to form a filter impurity layer. Since the impurity layer accumulates on the inner side of the fine filter, a pressure difference is formed between the inner and outer sides of the fine filter. . When the pressure difference of the filter reaches the preset value, the automatic cleaning process will start. During this time, the supply of clean water will continue to flow, the cleaning valve will be opened, and the water pressure in the cleaning chamber and the sewage suction device will drop significantly. The pressure difference generates a suction force between the suction pipe and the cleaning chamber through the suction nozzle, forming a sewage suction process. At the same time, the electric motor drives the sewage suction pipe to make a spiral motion in the axial direction. The axial movement of the dust collector is combined with the rotational movement to clean the inner surface of the entire filter screen. The entire flushing process takes only tens of seconds. The drain valve closes at the end of the cleaning. The filter begins to prepare for the next flush cycle.

1. Iron and steel: used for water treatment and filtration in raw material yards, sintering pelletizing plants, and cooling water filtration in blast furnaces, rolling mills, continuous casting machines and other systems.

2. Automobile: The coating production line is widely used in automobiles, tractors, motorcycles, engine manufacturing water, and treatment systems.

3. Power plants: used in the precision pretreatment part of the high-purity water preparation of power plant boilers, and the filtration of generator cooling water and sealing water.

Scraper self-cleaning filter

Similar ProductsVIEW MORE >