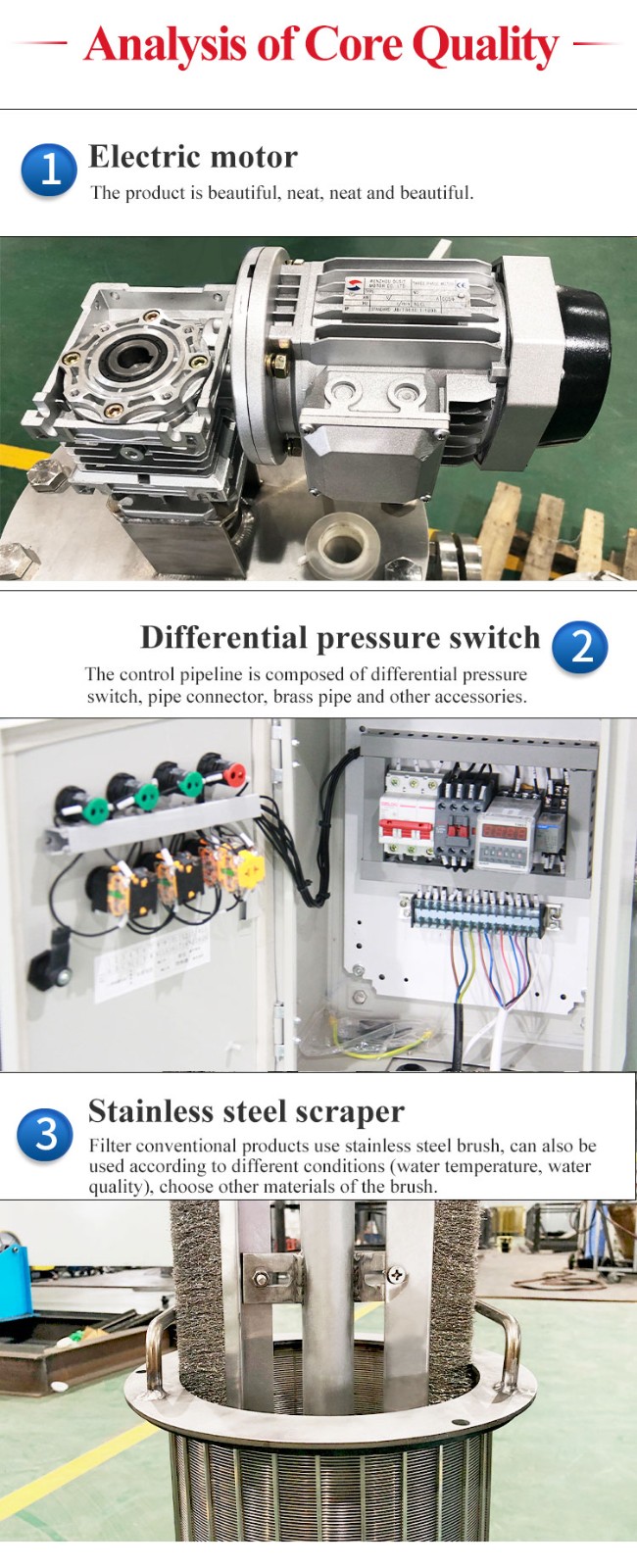

Vertical multi-element fine decontamination filter is a common filter in water treatment. The filter is composed of a shell, a filter element, a backwashing rotary mechanism, a differential pressure controller and an electric control part. Filter element adopts high strength wedge mesh or metal braided mesh filter element, through pressure difference, timing control backwash.

Vertical multi-filter element fine deconfouling filter element filtration and backwashing is a filter element in the filtration, the original (sewage) from the inside of the filter element to the outside filter, suspended impurities in the water by the V end of the gap hole in the filter element and floating around the gap plane, the filtered water from the filter element in the gap to the outflow. When the filter hole is blocked by a large number of suspended substances, the filter inlet and outlet water pressure difference increases, and start backwashing that is, the filter element in backwashing, backwashing because the inner cavity of the filter element is guided by the pressure relief valve and access to the atmosphere (gauge pressure is 0), so that the filter element outside the filtered water into backwashing water, under the action of large pressure difference rapidly washed from the filter element outside to the inside, because the gap is V-shaped, When backwashing water enters the inside from the outside of the filter element, the flow rate will be greatly increased, and then the formation of great scouring and cleaning effect on the gap. The V-shaped outward-facing high-quality filter element has excellent fluid characteristics, which can make the automatic backwash filter every time the automatic cleaning is successful, so as to ensure the long-term stable work of vertical multi-element filter. A large number of application practiceshave proved that if the filter element does not have the above characteristics, it will lead to the failure of filtration and backwashing.

1. The backwash pressure relief discharge port (DN3) is controlled by the electric valve and acts synchronously with the backwash motor, that is, the backwash motor starts to start the backwash electric valve opens and starts to discharge.

At the end of backwashing, the backwashing motor stops and the backwashing ends. The electric valve is also closed at the same time, and the discharge is over.

2. The sewage discharge outlet (DN4) is controlled by the manual valve. The manual sewage discharge valve should be opened regularly or opened during cleaning to discharge the dirt deposited at the bottom of the main engine.

3. The pressure equalization valve and air release valve should be opened and vented at the beginning of multiple operations, and should be closed during normal operation.

4. During installation, special attention should be paid to the inlet and outlet direction and no dirt with large particle size should enter the main engine. See the operation instruction for details.

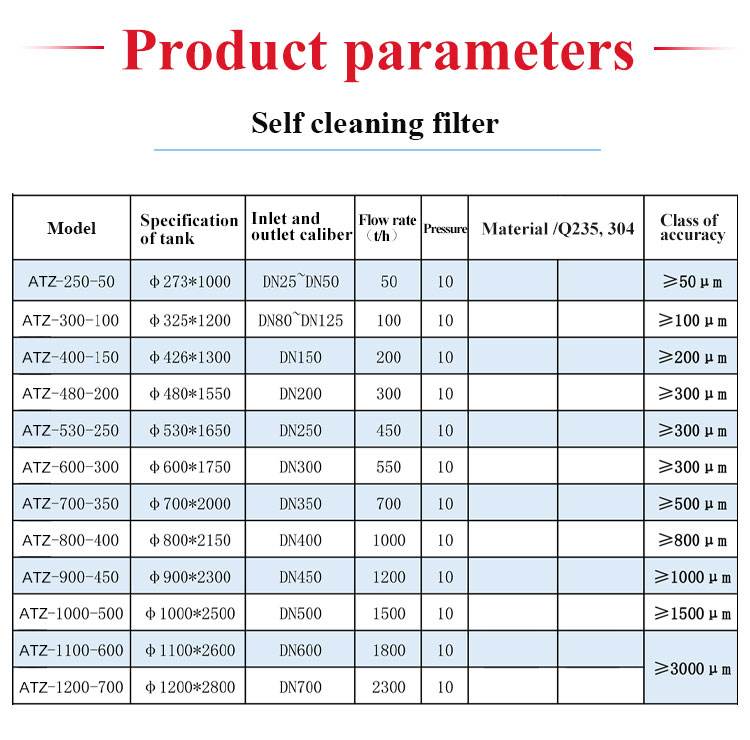

Model number: ATS-1804

Import and export specifications: DN250

Flow rate: 190t/h

Pressure: 10kg

Filtration media: all kinds of raw water pretreatment, as well as wastewater

Material: Carbon steel

Operating temperature :20℃-80℃

Form/structure: Stereoscopic

Filtration accuracy: High efficiency

Application: reverse osmosis, electrodialysis, ion exchanger, ultrafiltration and other systems of pre-treatment, power generation, chemical industry, paper making, beverage and other raw water filtration treatment

Vertical multi-element fine decontamination filter

Similar ProductsVIEW MORE >