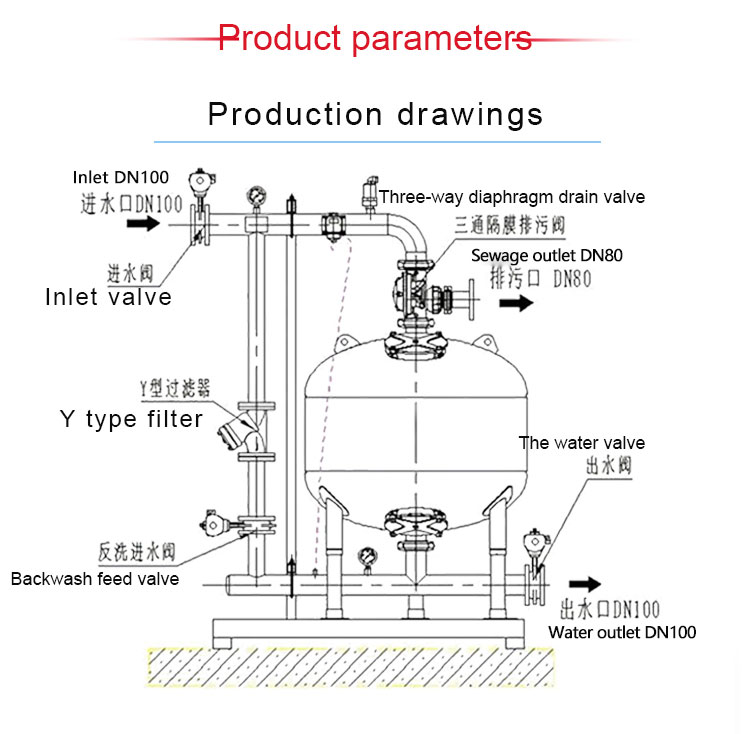

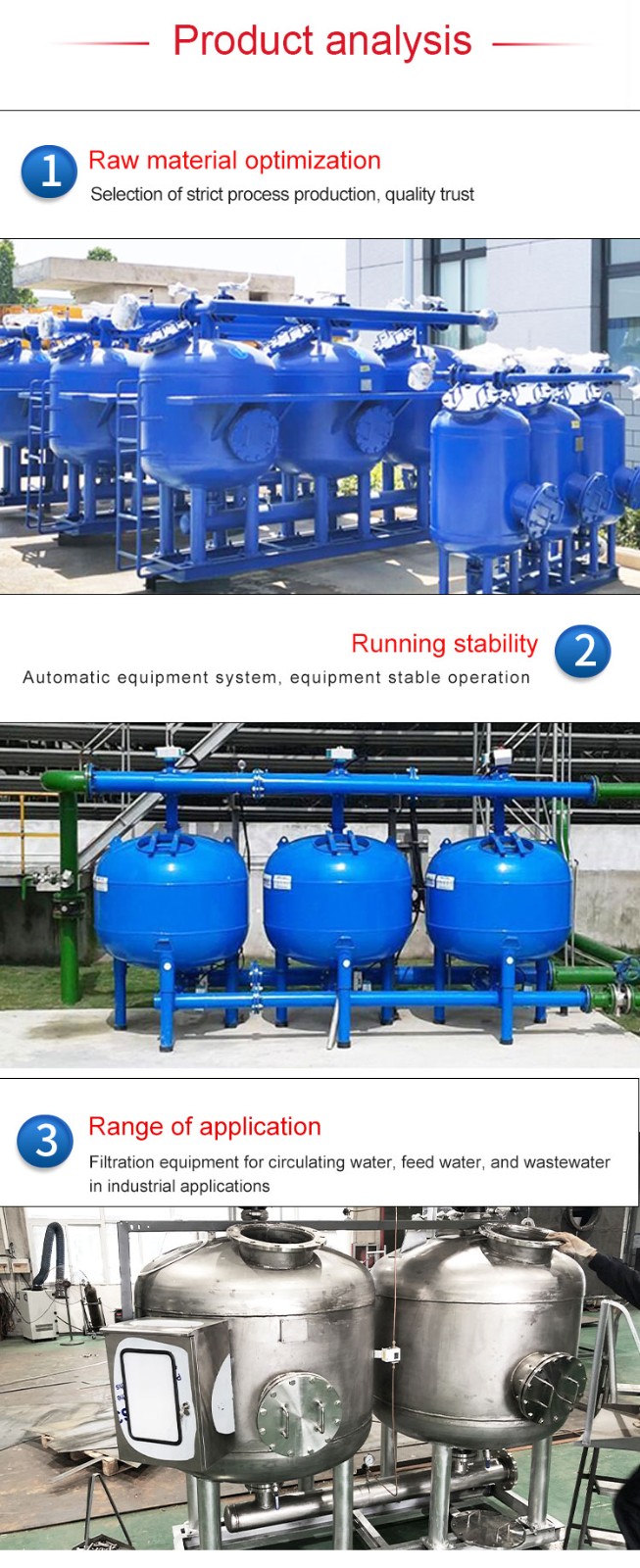

The multi-tank shallow sand high-flux filter is composed of one or more standard high-speed filtration units. The water flow through the internal water distributor and water collector can effectively remove particles and reduce turbidity by using different media.

Multi-tank shallow sand high throughput filter can be used as a standalone filtration system, using the supply water pump in the existing process, or if it is used as a by-filter, it can be equipped with its own pump separately. Filters can also be installed in multiple processing units on the common pipe, so that the system can achieve unlimited filtration capacity. The backwashing of the filter system can be done by manual, semi-automatic and fully automatic, which can be started by manual button, PLC, pressure difference or management system respectively. Backwash cycle and backwash time can be adjusted, set to 3 minutes when leaving the factory. This control is realized by PLC automatic filter control system.

Filter state: shallow filter, composed of a number of filter units parallel combination. When the system is in the filtering state, the unfiltered water is uniformly distributed through the self-developed unique water distributor, and the water passes through the packing layer (refined homogeneous quartz sand) in the filter in a laminar flow state. When water flows through the packing layer, impurities are trapped in the packing layer. The bottom of the filter has a plurality of evenly distributed water collector, the filtered water will be evenly collected and drawn out, advection filtration, can make the filter filter at high flow rate, still can achieve a better filtering effect.

Backwash state: with the continuous accumulation of impurities in the packing layer, the internal indenter loss will increase. When the loss of inlet and outlet water pressure heads reaches the set value, the system will automatically activate the constant differential pressure device to convert it to the backwashing state. When the backwashing is over, the hydraulic valve will change the water supply direction to realize backwashing one by one, which is more convenient to clean the accumulated impurities. When the system is in the state of backwashing, filtration still continues. The standard unit sand cylinder to be backwashed is not filtered, and other standard unit sand cylinders in the system are still filtered. The filtered clean water is used to backwash the standard unit sand tank, and the rest is sent to the user.

Backwash sewage is discharged through the backwash outlet of the hydraulic valve. In the high speed sand tank efficient filtration system, the special water collector design can make the fillers rub each other, maximize the backwash efficiency, reduce the required backwash water (clean water), at the same time there is no running material phenomenon in the backwash.

The backwashing time of one standard unit sand cylinder is 3 minutes. After the backwashing is finished, the loss of the pressure head inside the sand cylinder of the standard unit is reduced to a reasonable range, the constant pressure device gives a recovery signal, the hydraulic valve is restored to the filtering state, and the sand cylinder of the next standard unit is ready to enter the backwashing state. The system can also control the backwashing by time, and the default backwashing time is 4 hours. Adjust the time according to the working condition, dual system control regardless of primary and secondary, which first come first execution.

1. Treatment effect inlet turbidity: < 30FTU, outlet turbidity: < 10FTU;

2. Working environment parameters ①. Working temperature: 5-60℃; ②. Working pressure: ≤0.6MPa; ③. Inlet water pressure: ≥0.3MPa; (4) Backwash back pressure: ≥ 0.3MPa (if ≤0.3MPa need to add a regulator in the outlet pipe); Pressure difference between import and export: 0.02-0.05MPa.

3. Operating parameters ①. Working mode: pressure type; Operation mode: water flow from top to bottom; ③. Filtration speed: 30-60m/h; (4) Backwash mode: internal backwash; ⑤. Backwash water consumption: 1-3%; Backwash strength: 4-15L/s·m2; ⑦. Backwash duration: 10-15min; ⑧. Backwash expansion rate: 40-50%.

4. Control mode: manual control, automatic control (time)

5. Tank material: Q235B, 304, 316L, carbon steel liner. Water cap material: ABS, 304, 316L

6. Single flow :0.5m3/h~230m3/h,

7. Input voltage: AC22OV± 10% 50-60HZ

8. Output voltage: AC24V/ AC220V

9. Load power: 24W/1A

10. Power of each channel: ≤50W

Multi-tank shallow sand high throughput filter

Similar ProductsVIEW MORE >