It is composed of vacuum tank, vacuum pump, condensate tank, liquid accumulation tank and air replenishment system. The optimized structure design greatly increases the surface area of the oil in the vacuum system and prolongs the travel of the oil in the vacuum system. Make the water and gas in the oil fully escape

Vacuum system:

It is composed of vacuum tank, vacuum pump, condensate tank, liquid accumulation tank and air replenishment system. The optimized structure design greatly increases the surface area of the oil in the vacuum system and prolongs the travel of the oil in the vacuum system. Make the water and gas in the oil fully escape. This machine adopts advanced foam elimination system, so thatthe oil filter will not appear in the work of similar products commonly appear oil injection phenomenon.

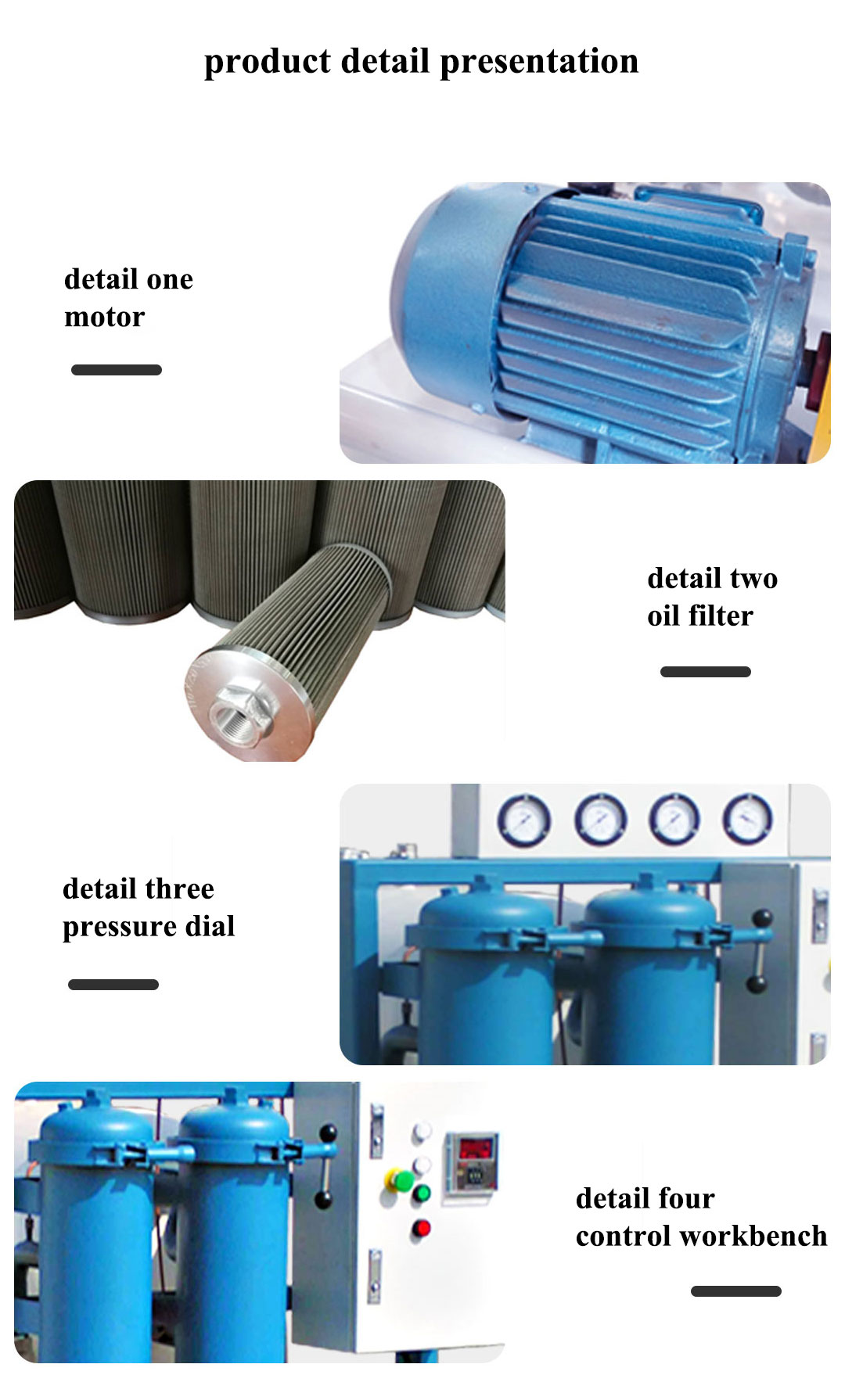

Filtration system:

Adopt three-stage filtration, oil suction port coarse filter to protect the oil pump and extend the service life of the main filter. After the pump is equipped with two stages of fine filter, so that the oil quickly reach a high cleanliness. Filter material with special gradient aperture glass fiber material, can be stratified filter particles of different size, greatly improve the service life of the filter element. With perfect structure of filter element, it can effectively reduce the surface flow rate of filter material and obtain stable filtration accuracy.

Heating system:

Step by step heating, surface heat load is less than 1.0W/cm2, will not overheat cause oil deterioration. Oil temperature can be adjusted in 0 ~ 100℃, automatic control, and equipped with a protective device, when the amount of oil is too small automatically stop working, avoid dry burning caused by the heater damage.

Automatic control system:

This machine adopts a series of automatic control instruments such as frequency converter, liquid level transmitter, temperature sensor, vacuum sensor to collect all kinds of information about the operation of the equipment, which is processed by the central processor to automatically control the operation of the whole equipment and monitor the operation status of the equipment. The machine is equipped with various protection devices (overload protection, overvoltage protection, phase sequence protection, abnormal operation stop protection), which can ensure the operation of the equipment.

Complete machine structure:

The integrated bridge structure reduces the volume. Adopt the integral detachable oil tank, ensure the ground oil free operation, reduce environmental pollution.

There are mobile, fixed, fully enclosed, vehicle and other models to choose from.

Thermal and nuclear power: used for turbine, boiler lubrication system, speed control system, bypass control system purification, feed water pump, fan and dust removal system purification.

Mechanical processing equipment: used for paper making machinery, mining machinery, injection molding machine and large precision machinery lubrication system and compressed air purification, tobacco processing equipment and spraying equipment dust recovery and filtration.

Industrial oil products: such as hydraulic oil. Transformer oil. Turbine oil. Refrigerating oil. Lubricating oil. Anti-fuel in the use process due to a variety of reasons will be mixed into some impurities, the main impurities are mechanical impurities, water and air, etc., these impurities will cause corrosion acceleration, increase mechanical wear, reduce work efficiency, make the oil deteriorate reduce the service life of equipment, serious will produce oil circuit blockage caused by production accidents.

Vacuum oil filter ZLYC-100

Similar ProductsVIEW MORE >