The vacuum plate oil filter has the characteristics of small volume, light weight, easy to move, low noise, long continuous working time, stable performance and easy operation

The vacuum plate oil filter has the characteristics of small volume, light weight, easy to move, low noise, long continuous working time, stable performance and easy operation. It is the ideal equipment for filtering transformer oil, turbine oil, 40# below oil, hydraulic oil and other oil in the water, gas and impurity particles in the power plant, power station, substation, electrical factory, oil refinery, petrochemical and other industrial and mining enterprises.

Connect the inlet and outlet oil pipeline, connect the 380V, connect the ground wire, check whether the circuit is connected, whether the valve of the oil pipeline is opened, and then carry out the operation procedure after the preparation is intact. First start the cooling water pump, check whether the water circulation is normal, and then click the vacuum pump, so that the oil in the vacuum pump can run normally, and then make the vacuum pump run continuously. When the vacuum surface reaches the limit, the oil inlet valve can be opened. When the lower window of the vacuum cylinder sees the oil level, the switch of the oil pump can be started, and the normal circulation of the oil circuit can be started to filter impurities. The heater switch can be opened to ensure the moisture in the volatile oil. If there is more water in the oil, the oil end in the vacuum cylinder will increase. At this time, it is necessary to open the gas to control the suitable vacuum degree. When the water is reduced and the oil drifts down, the air release valve will be closed to make the vacuum reach its limit. At this time, we should pay attention to the reaction of the instrument, if the pressure gauge reading is greater than 0.3MPa, said Ming and Qing filter paper suction more impurities, need to replace the filter paper, after the work, see the working principle, open the valve, so that the vacuum degree to normal atmospheric pressure, discharge the oil in the cylinder, the rest of the oil released from the oil plug, to prevent the next use mixed with different types of oil, In winter, pay special attention to clean the water in the vacuum pump and water tank, otherwise it will freeze the vacuum pump and water storage tank

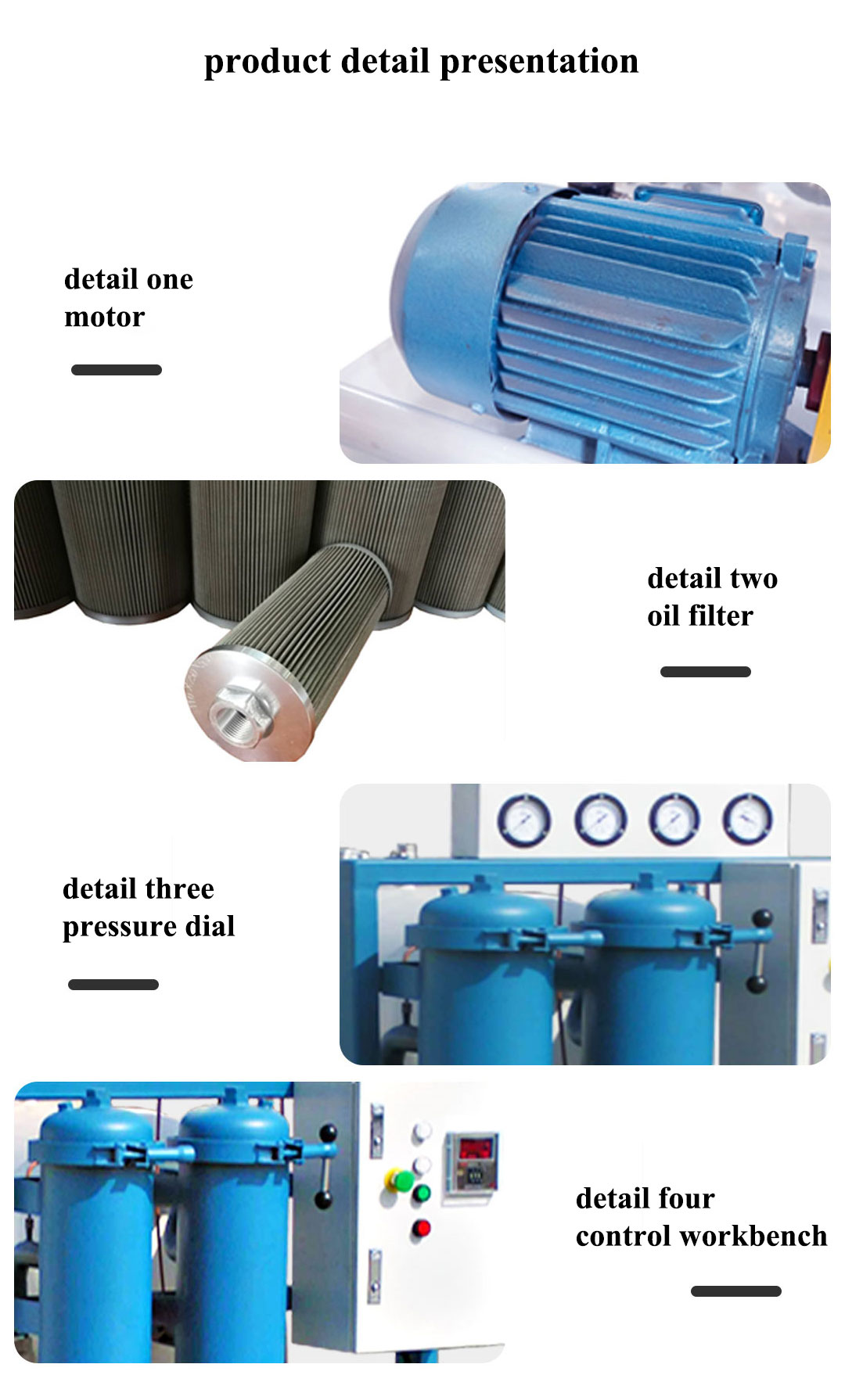

Vacuum type oil filter is designed according to the different principles of boiling point of water and oil. It is composed of vacuum heating tank fine filter, initial filter, water tank, vacuum pump, discharge oil pump and electric cabinet. Vacuum pump will vacuum tank air out to form a vacuum, the external oil under the action of atmospheric pressure, through the entrance pipe into the initial filter, remove large particles, and then into the heating tank, after heating such as 40~75℃ oil through the automatic oil drift valve, the valve is automatically controlled into the vacuum tank oil balance. The heated oil is separated into a semi-mist by the jet wing, and the water in the oil is quickly evaporated into steam and continuously sucked into the condenser by the vacuum pump. The water vapor entering the condenser is cooled and then released as water. The oil in the vacuum heating tank is discharged by the discharge pump into the fine filter through the oil filter paper or filter element to filter out the particulate impurities, so as to complete the whole process of the vacuum oil filter to quickly remove impurities, water and gas in the oil, so that the clean oil is discharged from the outlet.

Vacuum plate oil filter

Similar ProductsVIEW MORE >