ZL series oil vacuum filter automatic control system: This machine adopts a series of automatic control instruments such as frequency converter, liquid level transmitter, temperature sensor, vacuum sensor to collect all kinds of information about the operation of the equipment, which is processed by the central processor to automatically control the operation of the whole equipment and monitor the operation status of the equipment

ZL series oil vacuum filter automatic control system: This machine adopts a series of automatic control instruments such as frequency converter, liquid level transmitter, temperature sensor, vacuum sensor to collect all kinds of information about the operation of the equipment, which is processed by the central processor to automatically control the operation of the whole equipment and monitor the operation status of the equipment. The machine is equipped with various protection devices (overload protection, overvoltage protection, phase sequence protection, abnormal operation stop protection), which can ensure the operation of the equipment.

Applying the principle of solid and liquid, liquid and liquid, liquid and gas separation in fluid separation engineering, the filter medium through gravity separation technology, cyclone separation technology, vacuum vacuum separation technology, vacuum drying technology, three-dimensional flash evaporation technology, positive and negative pressure filtration technology and a variety of fluid precision filtration technology, To achieve rapid filtration of water, gas, impurities and other pollutants in the medium.

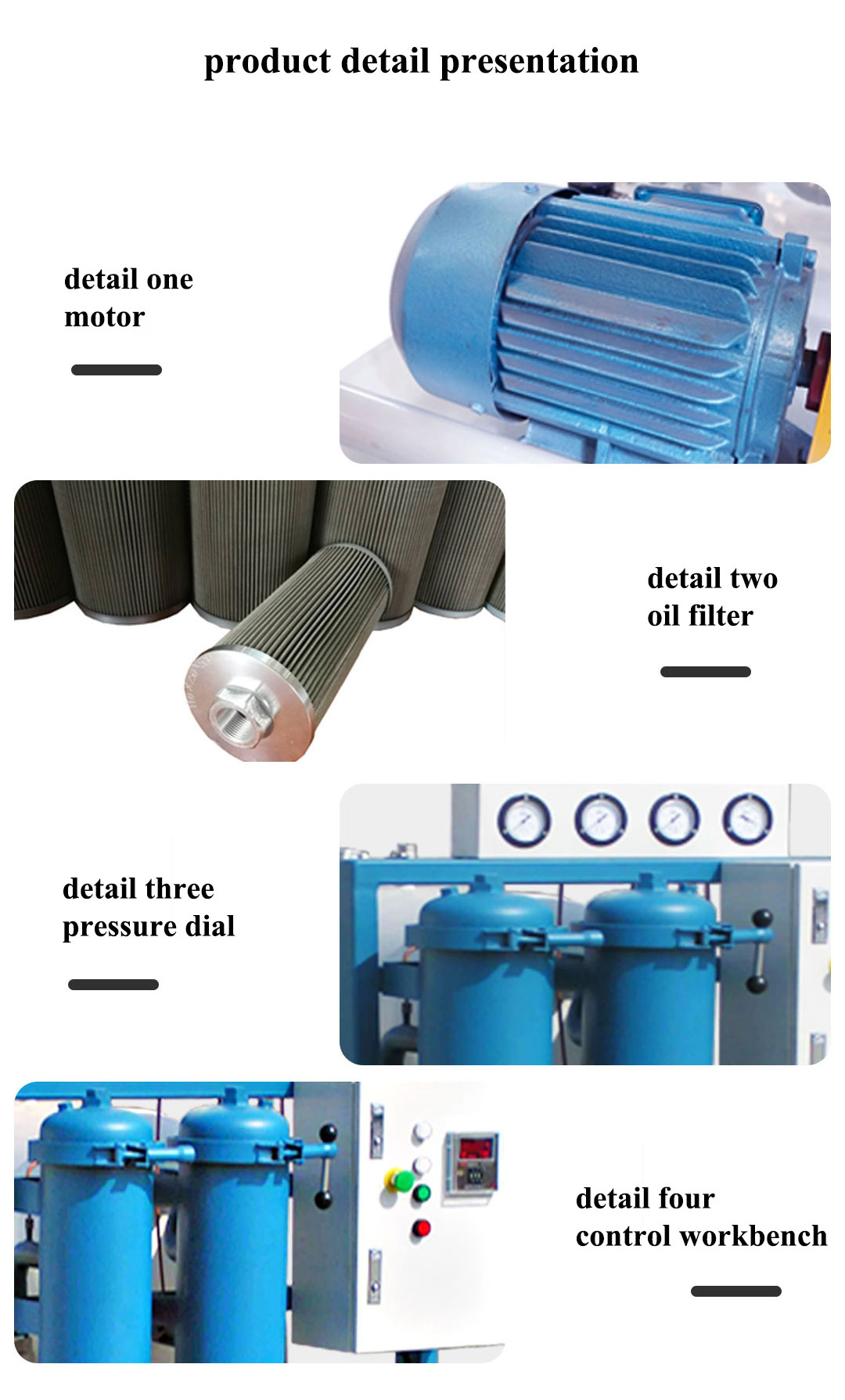

1. full automatic control, the whole machine operation only one button, at the same time with manual debugging function.

2. All links are equipped with protection or monitoring devices: motor overheating, overload, phase loss protection device, oil pump anti-air transfer protection device, heater anti-dry burning device, vacuum pump oil external circulation supplement tank, infrared automatic defoamer device, automatic liquid level control device, overpressure stop protection device.

3. especially the use of German fluid sensor, other main electrical appliances use Schneider, Siemens or Omron brand products, to ensure the accuracy and stability of the equipment control system.

4. A variety of separation technologies are comprehensively applied in the water removal system.

5. The factors conducive to water evaporation and separation, such as temperature, time, vacuum degree, evaporation and separation area and space, and the flow field distribution control, flow mode control, oil-water interface state control, oil-water interface height control, oil-water molecular foam thickness control, liquid level control and pressure control of the separation medium in the equipment are fully considered in the manufacturing process. Rapid separation of free water, dissolved water (micro water, emulsified water) is realized. Dehydration in one cycle reaches 60% of the water content in the oil.

6. impurity filtration system adopts multilevel large flux step by step encryption of a variety of filter materials (permanent/electromagnetic, stainless steel, copper, composite fiber, nylon, polypropylene, paper, etc.) filter element or filter bag, while integrating a variety of filtration technology (strong/electromagnetic, surface, deep absorption, adsorption filtration) application to ensure a filter impurities (different components, different shapes) purification rate of more than 90%.

7. vacuum evaporation degassing system can remove free gas and 85% of dissolved gas.

8. Equipped with plate-fin type air-cooled cooler produced by the company, the large temperature difference between the inside and outside of the equipment is formed, which further improves the water separation efficiency.

9. oil pump, vacuum pump domestic or imported optional.

Mainly used in machinery, metallurgy, mining, petroleum, petrochemical and other fields of hydraulic oil, mechanical oil, freezing oil, gear oil, gasoline, diesel engine oil, heat treatment oil of water, gas, impurities purification and filtration. Restore the performance of oil products to ensure the normal operation of hydraulic system, power system and lubrication system.

ZL series lubricating oil vacuum filter

Similar ProductsVIEW MORE >