Vacuum oil filter is used in power generation industry and electrical manufacturers, paper mills, electrochemical plants, industrial and mining enterprises of transformer oil, turbine oil (turbine oil), lubricating oil, hydraulic oil and other industrial oil degassing, impurity removal of filter water purification and waste oil regeneration, overcoming the general vacuum oil filter is only suitable for removing the shortcomings of micro-water oil treatment, is the ideal special equipment for oil purification

Vacuum oil filter is used in power generation industry and electrical manufacturers, paper mills, electrochemical plants, industrial and mining enterprises of transformer oil, turbine oil (turbine oil), lubricating oil, hydraulic oil and other industrial oil degassing, impurity removal of filter water purification and waste oil regeneration, overcoming the general vacuum oil filter is only suitable for removing the shortcomings of micro-water oil treatment, is the ideal special equipment for oil purification. The main function is dehydration, degassing, removal of mechanical impurities, parallel with the regeneration device can also remove acid, decolorization, improve insulation strength.

Compared with some similar products, this machine has the following characteristics:

1. small volume, light weight ratio, is the weight of similar products half.

2. Improved and perfected the design of the original oil-gas separator. By using vacuum oil inlet, a tubular rotary fuel injector is installed, which reduces the resistance, speeds up the rotation speed and increases the effect of oil and gas separation.

3. increase the regeneration and purification function of metamorphic oil. The previous vacuum oil purifier, just a single removal of impurities and water, this machine increases the silicone oil system, and the silicone oil and impurities filter into one, for mildly metamorphic transformer oil filter impurities, after the adsorption of silicone oil separator regeneration, so that it meets the standard of qualified oil.

4. One machine can do many things. This is an important feature of this machine. Because this machine is used in the field, and the original oil equipment is used as the oil storage tank, so that the hot oil circulation between the machine and the equipment, so that the three functions of oil filtration, regeneration, hot oil circulation and drying can be carried out at the same time, saving labor and saving time.

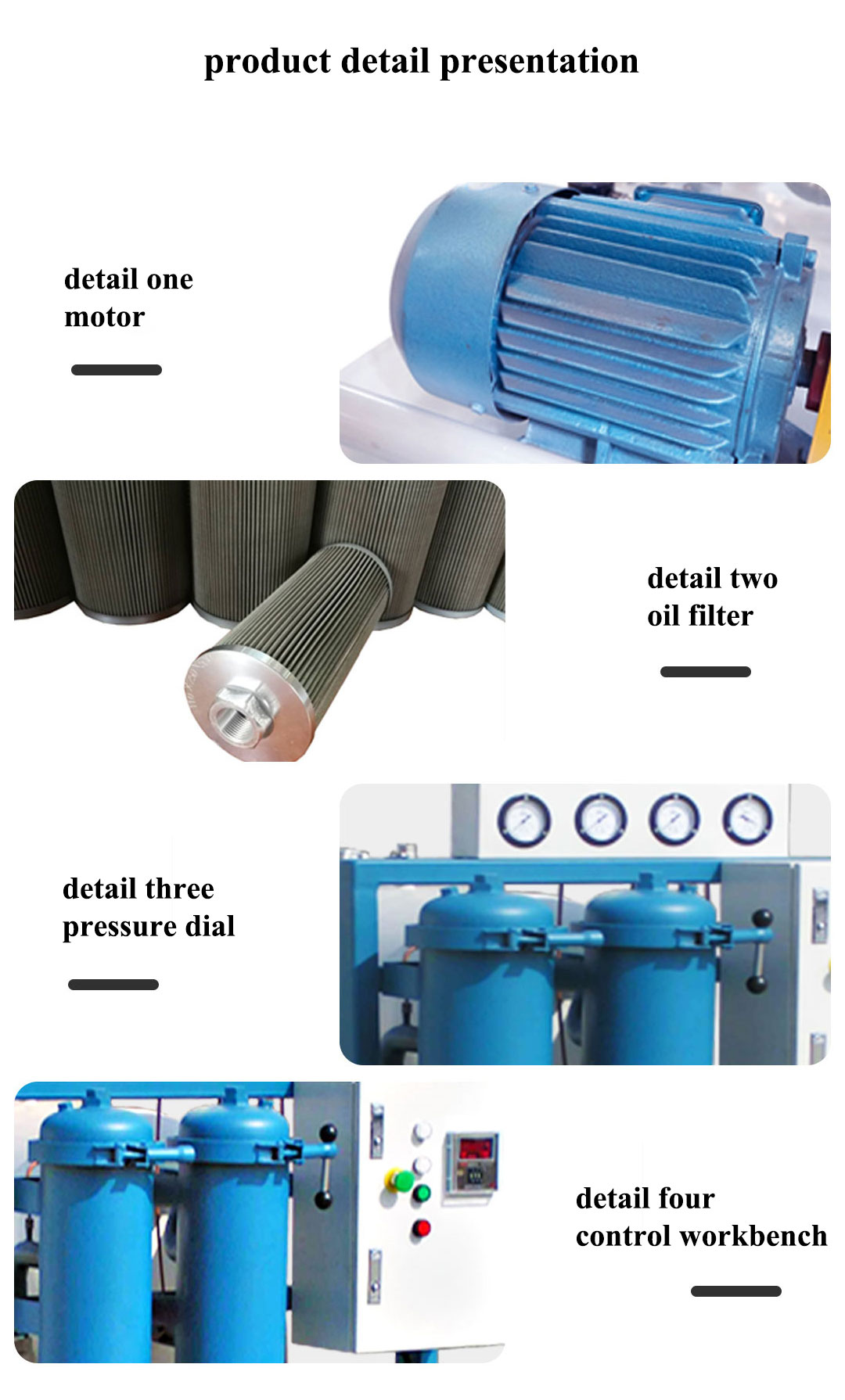

1. The vacuum system is composed of vacuum tank, vacuum pump, condensate tank, liquid accumulation tank and air replenishment system. The optimized structure design greatly increases the surface area of the oil in the vacuum system and prolongs the travel of the oil in the vacuum system. Make the water and gas in the oil fully escape. This machine adopts advanced foam elimination system, so that the oil filter will not appear in the work of similar products commonly appear oil injection phenomenon.

2. The filtration system adopts three-stage filtration, and the crude filter at the oil suction port protects the oil pump and prolongs the service life of the main filter. After the pump is equipped with two stages of fine filter, so that the oil quickly reach a high cleanliness. Filter material with special gradient aperture glass fiber material, can be stratified filter particles of different size, greatly improve the service life of the filter element. With perfect structure of filter element, it can effectively reduce the surface flow rate of filter material and obtain stable filtration accuracy.

3, the heating system adopts step by step heating, surface heat load is less than 1.0W/cm2, will not overheat cause oil deterioration. Oil temperature can be adjusted in 0 ~ 100℃, automatic control, and equipped with a protective device, when the amount of oil is too small automatically stop working, avoid dry burning caused by the heater damage.

4. The automatic control system adopts a series of automatic control instruments, such as frequency converter, liquid level transmitter, temperature sensor, vacuum sensor, etc. to collect all kinds of information about the operation of the equipment, which is processed by the central processor to automatically control the operation of the whole equipment and monitor the operation status of the equipment. The machine is equipped with various protection devices (overload protection, overvoltage protection, phase sequence protection, abnormal operation stop protection), which can ensure the operation of the equipment.

5. the whole machine structure integrated bridge structure, reduce the volume. Adopt the integral detachable oil tank, ensure the ground oil free operation, reduce environmental pollution. There are mobile, fixed, fully enclosed, truck-mounted and other models.

1. This machine can be used for all kinds of oil-immersed transformer, oil-immersed current voltage transformer and low-oil circuit breaker, for on-site oil filtering and oil filling.

2. this machine can be used for on-site hot oil cycle drying of the above equipment, especially for the oil immersion current, voltage transformer and less oil circuit breaker hot oil cycle drying is more effective.

3. This machine can be used for on-site vacuum oil filling and replenishing of sealing oil immersion equipment and equipment vacuum pumping.

4. this machine can also be used for slightly deteriorated transformer oil regeneration and purification, so that its performance to meet the standard of qualified oil.

Vacuum oil filter

Similar ProductsVIEW MORE >