Blast furnace gas drainer is composed of ordinary drainer and anti-leakage device, using the water seal height to overcome the gas pressure, so as to seal the gas, when the gas pipe network pressure fluctuation or other reasons caused by the drainage water level abnormal reduction, gas breakdown water seal, anti-leakage device action, close the overflow port, curb the gas leakage, prevent accidents.

Blast furnace gas drainer is composed of ordinary drainer and anti-leakage device, using the water seal height to overcome the gas pressure, so as to seal the gas, when the gas pipe network pressure fluctuation or other reasons caused by the drainage water level abnormal reduction, gas breakdown water seal, anti-leakage device action, close the overflow port, curb the gas leakage, prevent accidents.

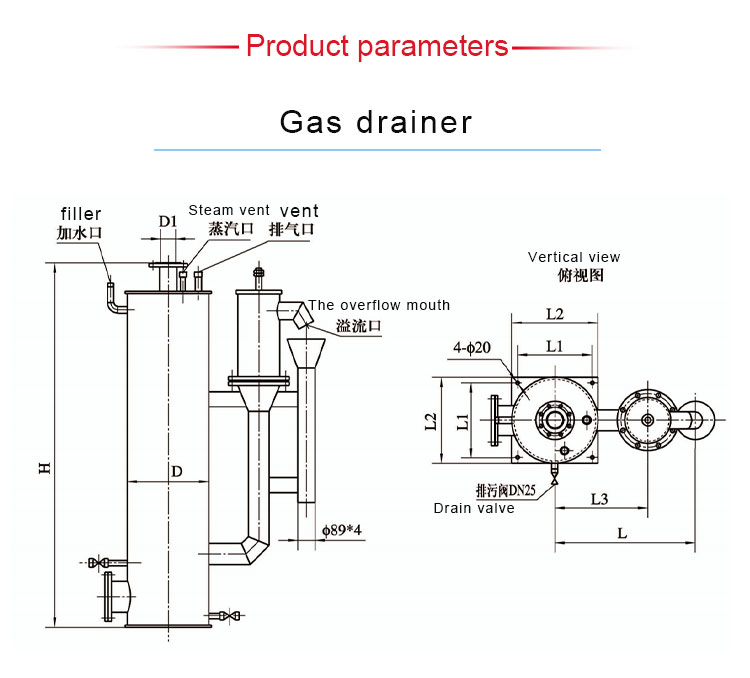

The main method is to connect the anti-breakdown and non-leakage gas drainer into the pipeline transporting gas. The condensate water in the gas pipeline enters the high pressure chamber of the drainer through the drain pipe, and then enters the low pressure chamber of the drainer through the connected pipe of the high and low pressure chamber on the partition board. The condensate water is collected and automatically discharged from the gas pipeline through the water seal, so as to ensure the normal operation of the equipment.

When the abnormally low water level of the drainer caused by the pressure fluctuation of the gas pipe network or other reasons is broken down by the gas, under the action of the gas impact, the anti-leakage device is triggered to close the overflow port, prevent the gas from leaking out, and ensure the normal operation of the equipment. In general, when the height of the water seal is greater than 2000mm, the structure of two or three chambers should be used to keep the overflow water outlet below 2000mm, so as to facilitate the observation of the working condition of the drainer.

1. Observe whether overflow water flows out of the overflow port. If there is no overflow water, check whether the overflow port is normal and timely water refill.

2. open the test valve, if there is gas discharge, the drainer is normal;

If water is discharged and gas is discharged after drainage, the lower part of the drainer is blocked, isolate the drainer, open the lower hand hole, clean and dredge, and then put into use;

If the test valve is opened, after the water is discharged, there is no gas discharge, then the upper part of the drainage pipe is blocked, close the upper part of the drainage valve, in the test port into the compressed air or industrial water, reverse dredge the down pipe, until the test port has gas discharge, then it can be used.

If it still cannot be dredged after measures are taken, block the blind plate of the downpipe and remove and dredge the downpipe.

3. Observe whether there is leakage in the drain valve. If there is leakage, close the lower gate valve and deal with it in time.

4. Check the buoy and conical sealing ring of the leakage prevention device every month to observe whether the buoy is deformed, corroded or leaked; Whether the sealing ring is worn.

Blast furnace gas drainer

Similar ProductsVIEW MORE >