NAS6 series high viscosity lubricating oil vacuum filter is used in machinery, metallurgy, mining, petroleum, chemical, electric power, transportation, railway and other fields, to purify all kinds of high viscosity lubricating oil products

NAS6 series high viscosity lubricating oil vacuum filter is used in machinery, metallurgy, mining, petroleum, chemical, electric power, transportation, railway and other fields, to purify all kinds of high viscosity lubricating oil products. It can quickly remove moisture, impurities, volatiles (such as ammonia) and other harmful components in oil, improve the quality of oil and restore its performance. This machine can run online, but also by preheating mailbox, to do separate processing of oil products, to meet the user's various processing requirements of oil products

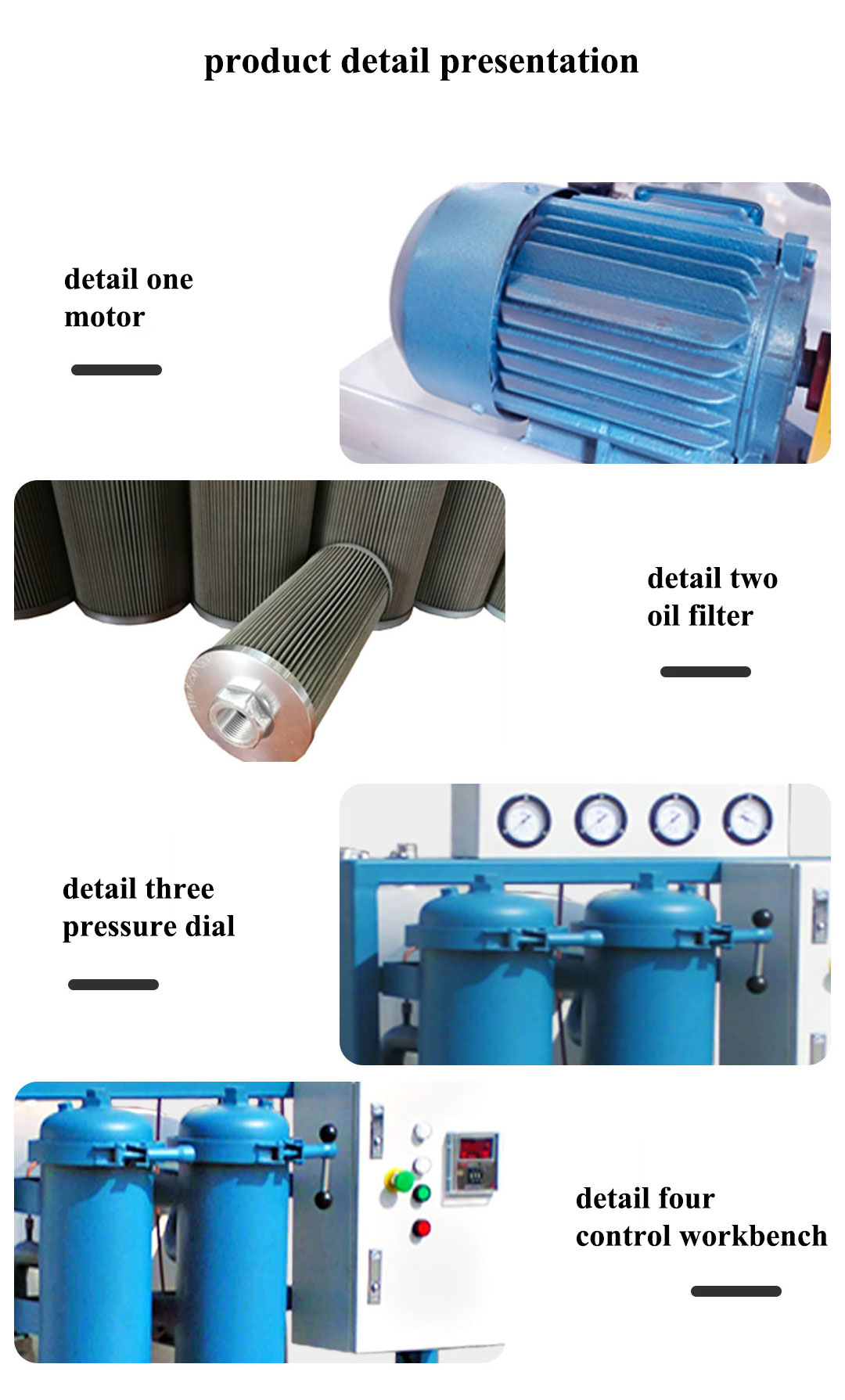

1. The use of technology won the invention award and the National Science and Technology Progress Award, can complete the high content dehydration and deep dehydration, impurity removal, degelatinization, demulsification, acid removal, decolorization, oil functions.

2. at the same time with centrifugal separation, molecular filtration, condensation dehydration, box filtration, pressure filtration, vacuum depth drying and other combined functions.

3. using fuzzy control technology, using Schneider electric appliances, reliable operation, long life.

4. with pressing overload protection, automatic dry burning, automatic foam elimination, automatic oil level control functions.

5. can synchronize with the unit online purification.

6. smooth operation, soft, small noise.

7. with environmental protection function, do not consume filter element.

8. Large filter diameter, strong contaminant capacity, long life and low maintenance cost.

Product use

It is mainly used for turbine oil treatment of generator set. It can remove moisture, gas and impurities in oil quickly and efficiently. Make the quality index of the oil products meet the new oil standard, ensure the normal operation of the unit adjustment and lubrication system, extend the maintenance cycle of the unit. Advanced hydrophilic and hydrophobic principles are adopted, dehydration and precision filtration are integrated, which can demulsify, dehydrate, remove acid and impurity online, making the turbidity and emulsification turbine oil clear and transparent. It is suitable for deep dehydration and purification of transparent oil, hydraulic oil, freezing oil and other lubricating oil which need to remove a lot of water and achieve precise filtration of impurities.

When the oil machine works, the oil enters the primary filter through the entrance under the action of internal and external pressure difference, the large particles of impurities are filtered out, the oil enters the secondary filtration after heating, and then enters the water distributor after filtering the smaller impurity particles. Because the water separator adopts the enhanced hydrophilic and hydrophobic technology, the interaction force between the oil and water two phases is changed, so that the small water droplets in the oil accelerate the movement, and the large water droplets are separated from the oil and precipitated in the water storage device. Then the oil is removed by the fine filter, and the oil enters the vacuum tank. The vacuum flash technology is used to remove the residual trace water in the oil. The evaporated water is cooled by the condenser or discharged by the vacuum system. The oil that removes the water is output by the oil pump to complete a clean oil process.

Turbine oil filter NAS6

Similar ProductsVIEW MORE >