Turbine oil vacuum filter is a filter equipment for turbine oil.

Turbine oil vacuum filter is a filter equipment for turbine oil.

1. polymer material as the medium, set emulsification, dehydration, impurity removal as one.

2. Compound stereo flash, with unique dehydration, degassing element, can quickly and effectively separate the water and gas in the oil.

3. Precision filtration system, can effectively remove all kinds of impurities, long service life of the filter element, large amount of pollution, with backwash function.

4. New electric heating system, low heating load, uniform heating, less energy consumption.

5. Automatic infrared level control instrument, pressure protection system, simple operation, reliable.

6. Use the whole machine interlock protection device, heater, oil pump, liquid level controller linkage work.

7. Can realize online operation with steam turbine, water turbine and other equipment.

Turbine oil vacuum filter is mainly used to deal with unqualified turbine oil, especially for severely emulsified turbine oil, can quickly remove water, gas, impurities in the oil. Make the quality index of oil products meet the new oil standard, ensure the operation of steam turbine unit. With special polymer material as medium, this machine integrates demulsification, dehydration and impurity removal. Combined with vacuum separation technology, it can demulsification, dehydration, acid and impurity removal online, making the turbidity and emulsification turbine oil become clear and transparent. It is the ideal equipment for on - line processing of turbine oil, low viscosity lubricating oil and hydraulic oil.

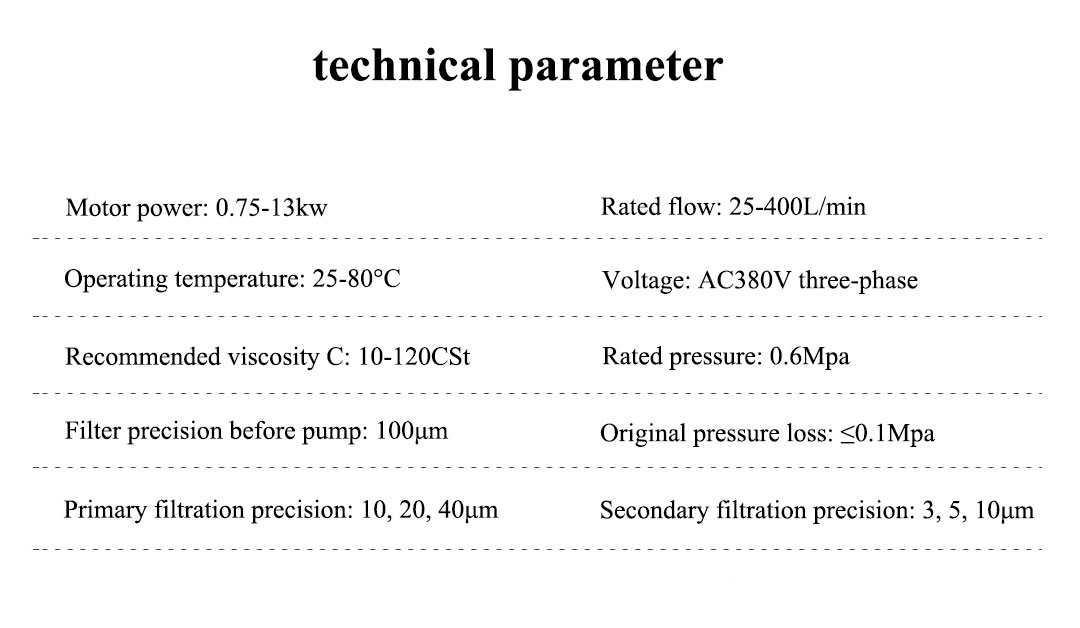

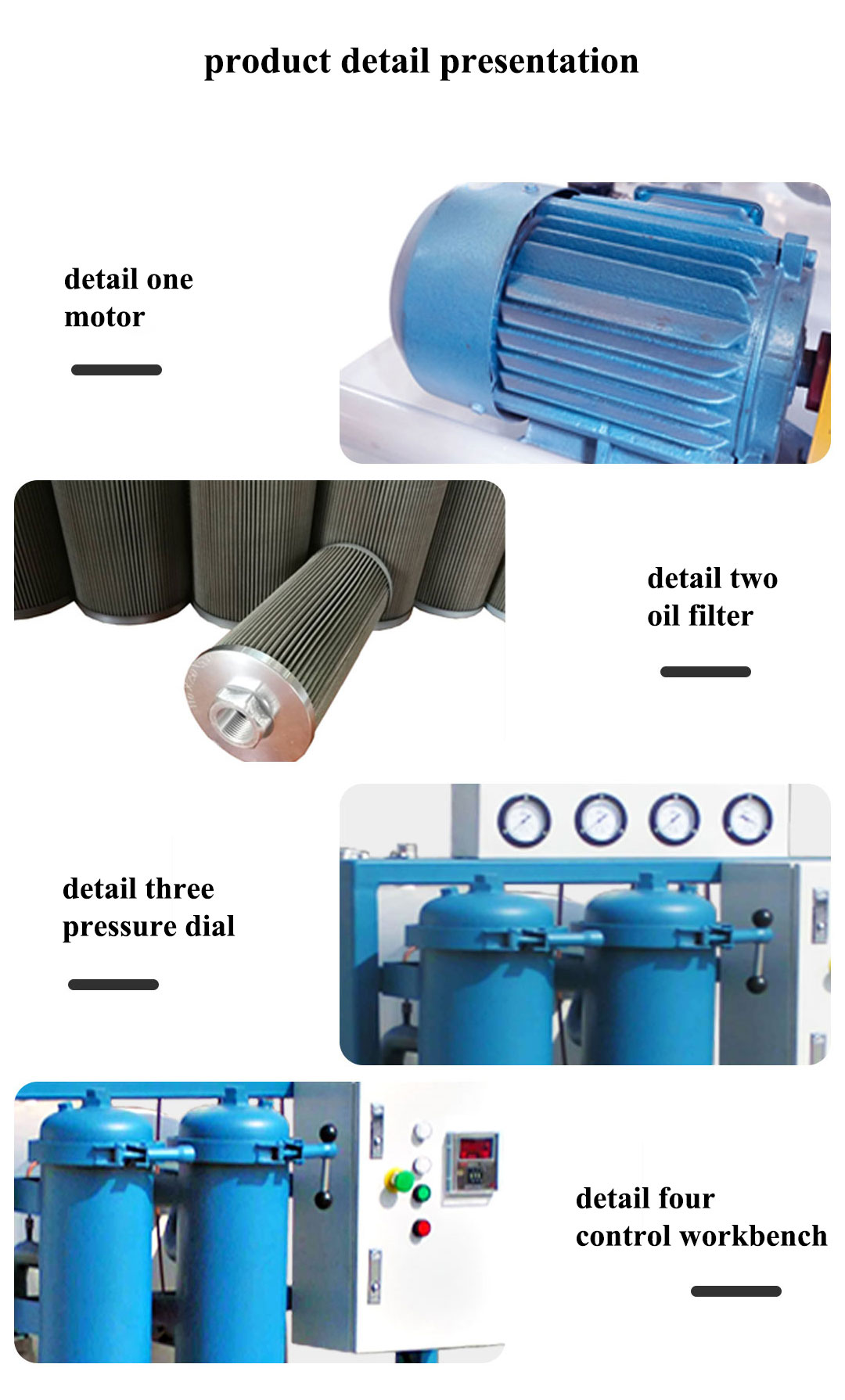

Turbine oil vacuum filter design according to the boiling point of water and oil is different, it is composed of main filter, heating system, fine filter, condenser, vacuum tank, fine filter, water tank, vacuum pump, discharge oil pump and electric cabinet. The vacuum pump extracts the air in the vacuum tank to form a vacuum, the outer oil acts under atmospheric pressure, goes through the intake pipe into the main filter to remove large particles, and then into the heating tank. After heating, such as 40 ~ 75°C, oil enters the vacuum tank through a solenoid valve which automatically controls the amount of oil flowing in and out of the vacuum tank. The heated oil becomes an oil mist and enters the vacuum tank. The water in the oil quickly evaporates into a steam sprayer and is sucked into the condenser of the vacuum pump. Water vapor passes through the back of the condenser to the liquid water and discharges. The gas in the oil is quickly discharged by a vacuum pump. After the vacuum tank, the oil passes through a fine filter to separate granular impurities, and then the clean oil is discharged.

Turbine oil vacuum filter

Similar ProductsVIEW MORE >